Introduction: The Critical Role of PP in Modern Food Service

In the competitive landscape of food service and distribution, packaging is no longer just a vessel; it is a critical component of product quality, brand perception, and operational efficiency. For restaurants, catering chains, and food manufacturers, choosing the right material can mean the difference between a satisfied customer and a spoiled delivery. Among the myriad of options available, the custom plastic PP packaging box stands out as the industry standard for versatility, safety, and durability.

Polypropylene (PP) has cemented its position as the material of choice for hot foods, microwaveable meals, and reusable food storage. Unlike PET or Polystyrene, PP offers a unique balance of thermal resistance and chemical inertness, making it indispensable for businesses that require packaging capable of withstanding the rigors of modern logistics—from the central kitchen to the freezer, and finally to the customer’s microwave.

This comprehensive guide is designed for procurement officers, operations managers, and brand owners. We will explore the technical specifications of PP, compare manufacturing processes like thermoforming and injection molding, and provide a detailed roadmap for sourcing wholesale food packaging that meets your exact requirements.

1. Understanding Polypropylene (PP): The Material Science

Before selecting a specific box design, it is essential to understand the material itself. Polypropylene is a thermoplastic polymer used in a wide variety of applications, but its properties make it uniquely suited for the food industry.

Thermal Resistance and Microwave Safety

The defining feature of a plastic PP packaging box is its high melting point, typically ranging between 160°C and 170°C (320°F – 338°F). This thermal stability allows PP containers to be placed directly into a microwave without warping, melting, or releasing harmful substances. For food service providers offering hot takeaways or heat-at-home meals, this is a non-negotiable requirement.

Chemical Resistance

PP is highly resistant to fats, oils, and organic solvents. In a food context, this means that acidic tomato sauces, oily curries, or vinaigrettes will not degrade the plastic or cause staining and pitting, which is a common issue with lower-grade plastics like polystyrene (PS).

Impact Strength and Flexibility

Polypropylene possesses a natural hinge property—it is tough and flexible. While it can crack under extreme cold if not modified, standard food-grade PP is durable enough to withstand the shocks and vibrations of transit without shattering. This durability reduces breakage rates during shipping, saving costs on damaged goods.

2. Manufacturing Processes: Injection Molding vs. Thermoforming

When sourcing a plastic PP packaging box manufacturer, you will typically encounter two main production methods. Understanding the difference is crucial for balancing cost, quality, and volume.

Injection Molded PP Boxes

Injection molding involves injecting molten PP into a precision-machined steel mold.

- Characteristics: These boxes have thicker walls, rigid structures, and high-precision details (like snap-fit lids and intricate venting systems).

- Best For: Reusable meal prep containers, premium takeaway bowls, and heavy-duty storage.

- Pros: Superior durability, premium feel, excellent seal integrity.

- Cons: Higher unit cost and higher initial tooling costs for custom shapes.

Thermoformed PP Boxes

Thermoforming involves heating a sheet of PP plastic and stretching it over a mold.

- Characteristics: Thinner walls, lighter weight, and more flexible.

- Best For: High-volume disposables, supermarket deli containers, and cost-sensitive takeaway applications.

- Pros: Lower unit cost, faster production rates, lower tooling costs.

- Cons: Less rigid, perceived as less “premium” than injection molded options.

For most businesses seeking a balance of quality and cost, exploring custom plastic PP packaging boxes that utilize advanced injection molding often yields the best ROI due to customer reuse and satisfaction.

3. Key Configurations and Design Options

One size does not fit all in the food industry. Manufacturers offer various configurations to suit specific menu items.

Compartmentalized (Bento) Boxes

Separating ingredients is vital for maintaining food quality. Multi-compartment PP boxes (2, 3, 4, or even 5 compartments) prevent sauces from making crispy items soggy. These are standard for meal prep services and set-meal deliveries.

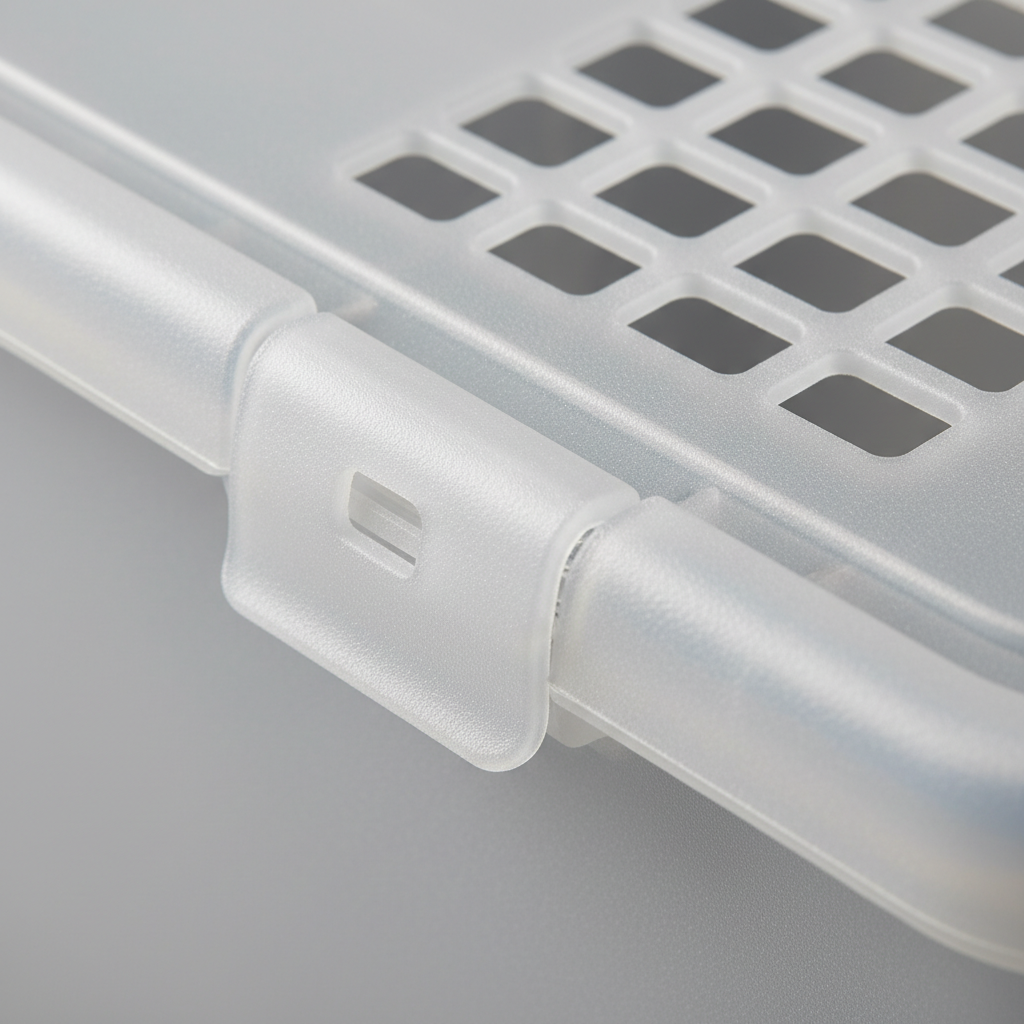

Vented Lids

Steam buildup is the enemy of texture. For fried foods or hot rice dishes, PP lids with precision-engineered vents allow steam to escape while retaining heat. This prevents the “sweating” effect that turns crispy chicken into a soggy disappointment.

Tamper-Evident Closures

Safety is paramount. Some PP packaging designs incorporate break-away tabs or safety locks that indicate if a container has been opened after packing. This feature is increasingly requested by delivery platforms to ensure food integrity.

4. Technical Specifications for Buyers

When requesting a quote from a plastic PP packaging box supplier, clarity on specifications will ensure you receive accurate pricing and samples.

Volume and Dimensions

Capacities are usually measured in milliliters (ml) or fluid ounces (oz). Common sizes include:

- 500ml / 16oz: Side dishes, small salads, rice portions.

- 750ml / 24oz: Standard single-serve meals.

- 1000ml / 32oz: Large entrees, soups, or shared sides.

Ensure you verify both the internal volume and the external dimensions to ensure the boxes fit your existing delivery bags or shelf spacing.

Wall Thickness (Gauge)

Measured in microns or mils. A higher gauge indicates a thicker, stronger box. For reusable-grade containers, look for substantial wall thickness that resists crushing when stacked.

Clarity and Color

Natural PP is translucent (hazy), not crystal clear like PET. However, high-quality “clarified PP” is available if product visibility is a priority. Alternatively, opaque black or white bases are popular for a sleek, professional look that hides food residue.

5. Customization and Branding

Your packaging is a mobile billboard. Generic packaging is a missed marketing opportunity. Here is how you can customize your printed plastic PP packaging box.

In-Mold Labeling (IML)

IML fuses the label with the container during the molding process. The result is a high-resolution, photographic-quality image that cannot peel off. This is ideal for retail products where shelf appeal is critical.

Dry Offset Printing

Direct printing onto the container surface (usually up to 6 colors). This is cost-effective for high volumes and works well for logos and simple branding elements.

Embossing/Debossing

For a subtle, premium touch, your logo can be embossed directly into the mold. This adds tactile branding without the cost of ink, though it requires a custom mold investment.

If you are unsure which method suits your budget, browse our wholesale food packaging solutions to see examples of what is possible.

6. Food Safety and Regulatory Compliance

Sourcing food grade plastic PP packaging boxes requires strict adherence to safety standards. Buyers must ensure that the manufacturer complies with relevant regulations for food contact materials.

BPA-Free Certification

While Bisphenol A (BPA) is less common in PP than in polycarbonates, reputable manufacturers will explicitly certify their PP products as BPA-free to reassure consumers.

Migration Testing

Quality PP packaging undergoes migration testing to ensure that chemical constituents do not transfer into the food, even under high heat or acidic conditions. Always ask your supplier for compliance documentation regarding local food safety standards (e.g., FDA, EFSA, or GB standards depending on your region).

7. Supply Chain and Logistics Considerations

Efficiency in logistics can significantly impact your bottom line. When ordering bulk plastic PP packaging boxes, consider the following:

Stackability and Nesting

“Nesting” refers to how well empty containers stack inside one another. A high nesting ratio means you can ship and store thousands of empty units in a small footprint, reducing warehousing and freight costs. Injection molded containers often have stacking lugs to prevent them from jamming together.

Minimum Order Quantity (MOQ)

Customization usually comes with higher MOQs.

- Stock items: Lower MOQs, faster delivery, generic appearance.

- Custom print/color: Higher MOQs (often 10,000+ units), longer lead time.

- Custom mold: Highest investment, requires tooling fees, but offers total exclusivity.

Lead Times

Production lead times vary based on seasonality and order complexity. Always plan 4–8 weeks ahead for custom orders, especially if sea freight is involved.

8. Sustainability: The Recyclability of PP

Sustainability is a major concern for modern buyers. Fortunately, Polypropylene is fully recyclable (Resin Identification Code 5).

Furthermore, the durability of injection-molded PP boxes encourages reuse. Unlike single-use Styrofoam, a high-quality PP container is often washed and reused by the end consumer for home storage, extending the product’s lifecycle and keeping your brand in their home longer.

9. Step-by-Step Buying Guide

Ready to place an order? Follow this checklist to streamline the process.

- Define the Menu: List the foods you will package. Are they hot, cold, liquid, or solid? Do they require venting?

- Determine Volume: Estimate your monthly usage to negotiate the best wholesale rates.

- Select the Type: Choose between cost-effective thermoformed or premium injection molded options.

- Design the Look: Decide on color (clear vs. black base) and branding (print vs. label).

- Request Samples: Never buy bulk without testing. Check the lid fit, leak resistance, and sturdiness.

- Verify Logistics: Confirm carton dimensions and pallet configurations to optimize shipping.

For a detailed walkthrough of the purchasing process, visit our how to order page.

10. Frequently Asked Questions (FAQ)

Q1: Can PP packaging boxes be frozen?

A: Yes, standard PP can withstand freezing temperatures, though it may become slightly brittle at extremely low temperatures (below -20°C). For deep-freeze applications, manufacturers can use impact-modified PP grades (copolymer PP) for better durability.

Q2: Is PP packaging waterproof and leak-proof?

A: PP material itself is waterproof. However, leak resistance depends on the lid design. Injection-molded containers with snap-fit lids generally offer excellent leak resistance for sauces and gravies.

Q3: What is the difference between PP and PET?

A: PET is crystal clear but cannot withstand high heat (it deforms above 60°C). PP is translucent (hazy) but heat-resistant up to ~165°C. Use PET for cold salads; use PP for hot meals.

Q4: How do I customize the size of the box?

A: Custom sizes require creating a new steel mold. This involves a tooling fee and is typically only cost-effective for high-volume orders (e.g., 50,000+ units).

Q5: Are these boxes microwave safe?

A: Yes, PP is the industry standard for microwave-safe plastics. It does not warp or melt under normal reheating conditions.

Q6: Can I get a sample before ordering in bulk?

A: Absolutely. We recommend testing samples with your actual food products to ensure the fit and capacity are correct. You can contact our team to request samples.

Q7: What artwork format is needed for printing?

A: Vector files (AI, PDF, EPS) are required for clear, crisp printing. Ensure all fonts are outlined and colors are specified in Pantone (PMS) codes.

Conclusion

Selecting the right custom plastic PP packaging box is a strategic decision that impacts food quality, operational costs, and brand image. By prioritizing thermal stability, leak resistance, and functional design, you ensure that your culinary creations arrive at the customer’s table exactly as intended.

Whether you need a standard wholesale solution or a fully customized branded container, understanding the technical nuances of Polypropylene empowers you to make the best choice for your business.

Ready to upgrade your food packaging? Request a quote today or browse our catalog to find the perfect fit for your menu.