Introduction: More Than Just a Container

In the competitive food service industry, the humble pizza box serves a critical triple function: it is a thermal insulator, a structural protector, and a mobile billboard. For B2B buyers—whether you are a procurement manager for a restaurant chain, a distributor sourcing for local pizzerias, or a brand owner launching a frozen pizza line—choosing the right custom pizza paper box is a decision that impacts product quality, customer satisfaction, and operational costs.

Sourcing packaging at a wholesale level requires navigating a complex landscape of material specifications, flute profiles, print technologies, and compliance standards. A box that is too flimsy will collapse under the weight of a stacked delivery. A box with poor ventilation results in a soggy crust. A box with inadequate grease resistance leads to unsightly staining that damages your brand image.

This comprehensive guide explores the technical and commercial aspects of sourcing pizza paper boxes. We will break down the nuances of corrugated board grades, standard and custom sizing, printing options for maximum brand impact, and the logistics of bulk ordering.

1. The Anatomy of a Professional Pizza Box

To the end consumer, a box is just cardboard. To a buyer, it is an engineered structure composed of specific paper grades and fluting profiles designed to withstand heat, moisture, and weight.

Corrugated Board: The Industry Standard

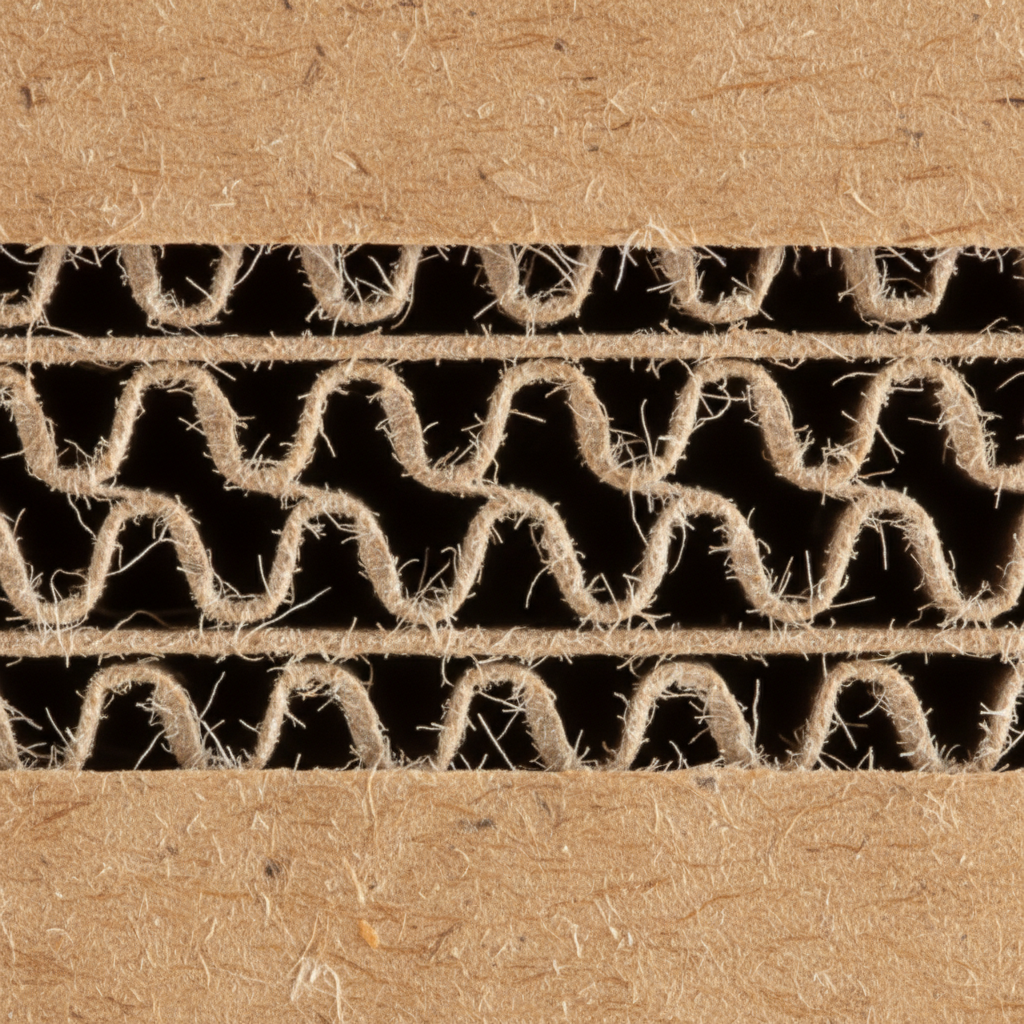

The vast majority of hot food pizza boxes are made from corrugated fiberboard. This material consists of three layers:

- The Outer Liner: The face of the box that carries your branding.

- The Medium (Fluting): The wavy inner layer that provides cushioning, insulation, and stacking strength.

- The Inner Liner: The surface that faces the food (often treated for grease resistance).

Flute Profiles: E-Flute vs. B-Flute

The “flute” refers to the wave size of the corrugated medium. Choosing the right flute is essential for balancing storage space, heat retention, and stacking strength.

- E-Flute (Micro-Flute): This is the most common profile for modern pizza boxes. It is approximately 1.5mm to 2mm thick. E-flute offers a superior printing surface because the flutes are closer together, reducing the “washboard” effect on the outer liner. It is rigid, space-efficient for storage, and provides excellent thermal insulation for standard pizzas.

- B-Flute: Thicker than E-flute (approx. 3mm), B-flute was the industry standard for decades. It offers higher stacking strength and better cushioning for heavier items (like deep-dish pizzas or large calzone orders). However, it takes up more warehouse space and the print quality is generally slightly rougher than E-flute.

Paper Grades and GSM

The strength of the box is also determined by the Grams per Square Meter (GSM) of the paper used. A typical high-quality pizza box might use:

- Outer Liner: 140–175 GSM Kraft or White Top Kraft.

- Medium: 110–120 GSM High-Performance Fluting.

- Inner Liner: 120–140 GSM Test Liner or Kraft.

For wholesale buyers, specifying the paper grade ensures you aren’t sold a “budget” box that feels flimsy in the customer’s hands.

2. Material Selection: Kraft vs. White vs. Clay Coated

Your choice of material dictates both the aesthetic appeal and the cost structure of your packaging.

Brown Kraft (Natural)

Brown Kraft is the default choice for many pizzerias emphasizing an eco-friendly, rustic, or artisanal image. It is generally more cost-effective than white paper. Because the fibers are unbleached, Kraft paper retains high structural integrity.

Best for: 1-2 color flexographic printing, eco-conscious brands, and cost-sensitive high-volume orders.

White Top Kraft

This features a bleached white outer layer with a brown interior. The white surface acts as a canvas for brighter, more vibrant colors. If your brand colors include bright yellows, reds, or blues, they will pop significantly more on white paper than on brown.

Clay Coated News Back (CCNB)

While less common for hot delivery, CCNB is often used for frozen pizza retail boxes (primary packaging). It provides a smooth, glossy surface ideal for high-resolution offset printing but lacks the thermal insulation of corrugated board. For delivery, stick to corrugated; for the freezer aisle, consider CCNB.

3. Structural Design and Sizing

One size does not fit all. While 12-inch and 16-inch boxes are staples, optimizing your size range can save material costs and improve product presentation.

Standard Dimensions

Most manufacturers offer standard tooling for the following square sizes:

- 10″ (Small / Personal): often 10x10x1.75 inches.

- 12″ (Medium): often 12x12x1.75 inches.

- 14″ (Large): often 14x14x1.75 inches.

- 16″ (X-Large): often 16x16x1.75 inches.

- 18″ (Jumbo): often 18x18x2 inches.

Height Matters

The standard height is usually 1.5 to 1.75 inches. However, if you serve Chicago-style deep dish or heavily topped pizzas, a standard height box will result in the lid touching the cheese. In these use cases, specifying a 2-inch or 2.5-inch height is mandatory to protect the product integrity.

Venting and Locking Mechanisms

Ventilation: Steam is the enemy of a crispy crust. Custom pizza boxes should feature die-cut vent holes, typically on the rear or side panels. These allow excess moisture to escape without cooling the pizza too rapidly.

Corner Styles:

- Pizza Style (Locking Corners): The front flap tucks into the sides. This is the most secure for delivery.

- Clamshell: Often used for smaller sizes or slices. Faster to close but less rigid.

4. Grease Resistance and Food Safety

Grease migration is a major concern for food packaging boxes. If grease soaks through the bottom, it can stain car seats, clothing, and tables, reflecting poorly on the brand.

Liner Treatments

To combat this, the inner liner of the box can be treated. There are generally two approaches:

- High-Sizing Kraft: The paper is manufactured with additives that naturally resist liquid absorption. This is suitable for standard pizzas with average grease content.

- Aqueous Coatings / Barriers: A water-based coating applied to the inner liner. It provides a higher “Kit Level” (a measure of grease resistance).

Note on Recyclability: Historically, poly-coatings (plastic) were used for grease resistance, but these render the box difficult to recycle. Modern aqueous coatings and high-density papers offer a balance of performance and recyclability, which is increasingly important for international compliance.

5. Printing Technologies: Branding Your Box

The pizza box is the first thing a customer sees when their order arrives. It is a prime marketing real estate.

Flexographic Printing (Flexo)

This is the industry standard for wholesale pizza paper boxes. It uses flexible relief plates and fast-drying inks.

Pros: Low unit cost for high volumes; water-based inks are food-safe; fast production.

Cons: Cannot achieve photo-realistic images; gradients can be stepped; usually limited to 3-4 colors.

Best Use: Logos, contact info, bold graphics, and simple patterns.

Offset Printing (Lithography)

For brands that require photographic quality, complex gradients, or premium finishing.

Pros: Superior image quality; tight registration.

Cons: Higher tooling/setup costs; often requires a process called “litho-lamination” where a printed sheet is glued to the corrugated board, adding cost.

Best Use: Premium gourmet brands, promotional boxes, or retail packaging.

Digital Printing

Pros: No plate costs; perfect for short runs or seasonal promos.

Cons: High unit cost; slower production speeds.

Best Use: Samples, limited edition drops, or market testing.

6. Manufacturing and Quality Assurance

When partnering with a pizza paper box manufacturer, understanding their QA process is vital. Inconsistent production leads to boxes that don’t fold square or collapse when stacked.

Key Quality Metrics

- ECT (Edge Crush Test): Measures the stacking strength. A standard pizza box should have an ECT rating sufficient to hold the weight of 5-10 filled boxes without buckling.

- Bursting Strength (Mullen Test): Measures the force required to puncture the face of the board. Important for protecting the pizza from external impacts.

- Die-Cut Accuracy: If the die-cutting tolerance is off, the locking tabs won’t fit securely, slowing down your kitchen staff during the folding process.

7. Buying Guide: Sourcing Strategy

Effective procurement involves balancing Minimum Order Quantities (MOQs) with unit costs and storage capabilities.

MOQ Considerations

Custom printing requires setup.

Small Runs (500–1,000 units): Often relegated to digital print or stock boxes with stickers. Unit costs are high.

Mid-Range (5,000–10,000 units): The sweet spot for independent chains. Flexo printing becomes economical.

Bulk (Container Load): For distributors and large chains. This offers the lowest unit price but requires significant warehousing.

Artwork Preparation

To ensure your custom boxes look crisp, supply your manufacturer with vector artwork (AI, PDF, EPS). Raster images (JPEG, PNG) will pixelate when printed on the porous surface of corrugated board.

Logistics and Storage

Pizza boxes are shipped flat (knocked down) to save space. However, paper is hygroscopic—it absorbs moisture from the air.

Tip: Store your boxes in a dry, climate-controlled environment. High humidity can soften the corrugated board, reducing its stacking strength by up to 50%.

8. Frequently Asked Questions (FAQ)

What is the difference between E-flute and B-flute for pizza boxes?

E-flute is thinner (approx 1.5mm), offers better print quality, and saves storage space. B-flute is thicker (approx 3mm) and stronger, better suited for very heavy pizzas or large stacks.

Are pizza boxes recyclable if they have grease on them?

Heavily soiled boxes are often rejected by recycling plants because grease interferes with the pulping process. However, boxes with minimal staining or those using high-quality grease-resistant liners that prevent soak-through are more likely to be accepted. Compostable certification is an alternative route for disposal.

What is the lead time for custom printed pizza boxes?

Lead times vary by season and manufacturer workload. Generally, after artwork approval, production takes 2–4 weeks. Shipping times depend on your location relative to the factory. Always plan 8–10 weeks ahead for new designs.

Can I get a sample before placing a bulk order?

Yes. Most reputable suppliers offer plain samples to check size and material quality. Printed proofs (prototypes) may incur a small fee due to the setup required, but are highly recommended for checking color accuracy.

Do you offer food-grade certification?

Professional manufacturers use paper and inks that comply with international food safety standards (such as FDA or EU regulations). Always ask for compliance documentation when vetting a new supplier.

How do I determine the right box size for my pizza?

Ideally, the box should be 0.5 to 1 inch wider than the pizza diameter to prevent movement without wasting material. If you sell a 12-inch pizza, a 12-inch box is standard, but ensure your dough stretching is consistent so it fits!

Conclusion

Choosing the right pizza paper box is a balance of engineering, marketing, and economics. It requires selecting the right material grade to keep the food hot and crisp, the right print method to build your brand, and the right partner to ensure consistent supply.

Whether you need a high-volume run of standard Kraft boxes or a premium, full-color package for a gourmet line, understanding these specifications puts you in control of the buying process.

Ready to upgrade your packaging? Contact our team today to discuss your specifications, or request a quote for custom printed pizza boxes tailored to your brand.