Introduction: The Strategic Importance of Paper Lunch Containers in Modern Food Service

In the competitive landscape of food service, packaging is no longer just a vessel for transporting meals; it is a critical component of brand identity, operational efficiency, and environmental responsibility. For procurement managers, restaurant chains, and food distributors, selecting the right paper lunch containers involves navigating a complex matrix of material specifications, functional requirements, and supply chain logistics.

The shift away from single-use plastics has accelerated demand for high-quality paper-based solutions. However, not all paper containers are created equal. A container that fails to hold grease can ruin a customer’s experience, while over-engineered packaging can unnecessarily inflate costs. This guide provides a comprehensive technical analysis of paper lunch containers, designed to help B2B buyers make informed decisions when sourcing paper lunch containers wholesale.

We will explore the nuances of paper grades, barrier coatings, structural designs, and customization options, ensuring that your packaging strategy aligns with both your operational needs and your brand values.

1. Core Material Specifications: Understanding Paper Grades

The structural integrity of a lunch container begins with the raw material. In the manufacturing of food-grade packaging, the choice of paperboard determines the container’s stiffness, printability, and resistance to moisture. Most industrial buyers will encounter two primary categories: Kraft and Bleached White Paperboard.

Virgin Kraft Paperboard

Virgin Kraft is produced from unbleached wood pulp. It is renowned for its superior strength and tear resistance due to the long fibers retained during the pulping process.

- Appearance: Natural brown, rustic, eco-friendly aesthetic.

- Strength: High tensile strength, making it ideal for heavier meals or stacking during delivery.

- Use Case: Brands emphasizing sustainability, organic ingredients, or hearty, heavy meals.

Bleached White Paperboard (SBS)

Solid Bleached Sulfate (SBS) is a premium paper grade produced from bleached chemical pulp. It offers a pristine white surface both inside and out.

- Appearance: Clean, bright white surface that provides excellent contrast for vibrant, full-color printing.

- Printability: The smooth surface allows for high-resolution graphics, making it the preferred choice for brands with complex logos or specific color matching requirements (Pantone/CMYK).

- Use Case: Premium dining, sushi, bakery items, and brands requiring sharp, colorful graphics.

Recycled Paperboard (CRB/CNK)

While sustainability is a priority, recycled paperboard (Coated Recycled Board or Coated Natural Kraft) is often used with caution in direct food contact applications. If used, it typically requires a functional barrier to ensure food safety and prevent migration of mineral oils. Buyers should always confirm that recycled materials meet FDA or local food safety standards for direct contact.

Grammage (GSM) and Thickness

Paper weight is measured in Grams per Square Meter (GSM). For lunch containers, the GSM directly correlates to the box’s ability to hold shape under the weight of food and moisture.

- 250–280 GSM: Suitable for small snack boxes or dry foods (fries, pastries).

- 300–337 GSM: The industry standard for most lunch containers. It balances cost with structural rigidity.

- 350+ GSM: Used for large, family-sized containers or heavy, wet dishes requiring extra durability.

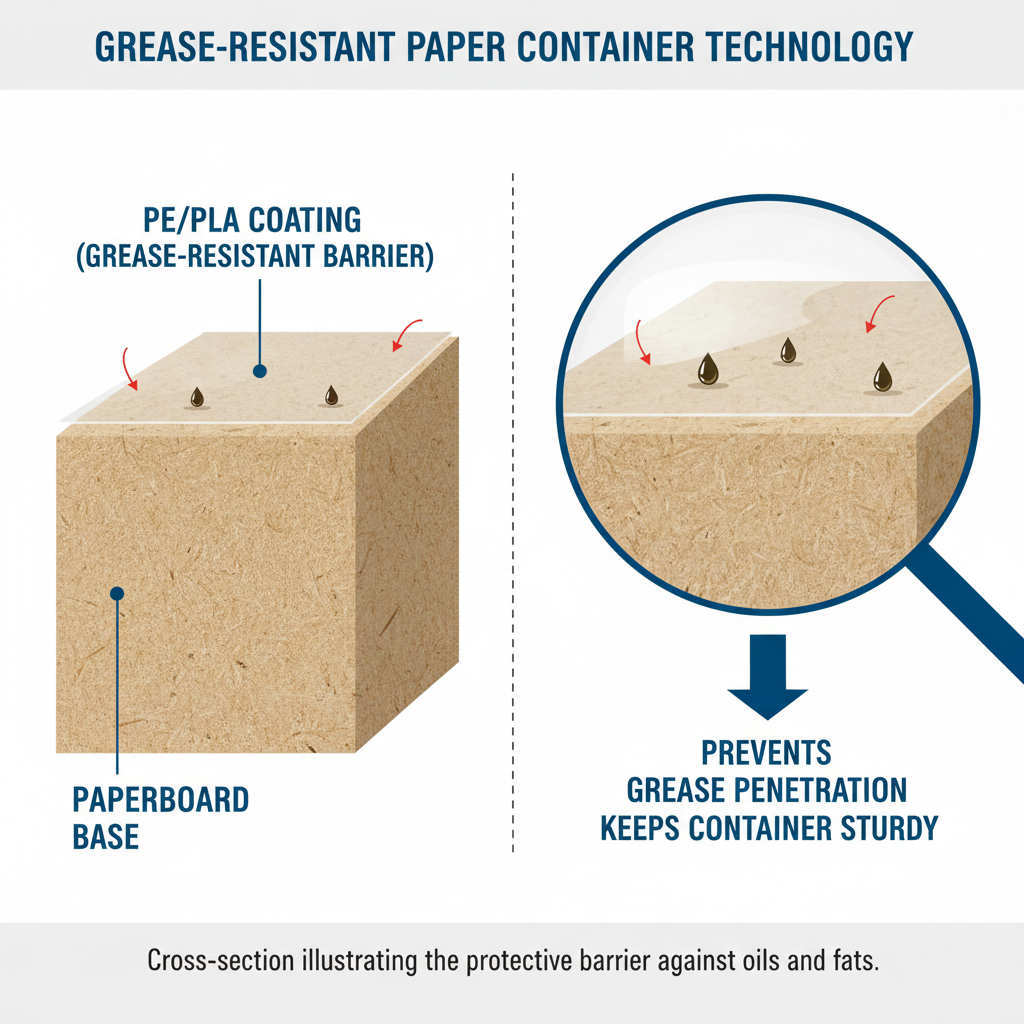

2. Barrier Coatings: Grease and Moisture Resistance

Paper is naturally porous and absorbent. To function as a food container, it requires a barrier coating. This is the most technical aspect of selecting food packaging boxes, as the wrong coating can lead to leaks and soggy bottoms.

Polyethylene (PE) Coating

PE is the traditional industry standard for lining paper containers. It is a thin layer of plastic applied to the paperboard.

- 1PE (Single Poly): Coating on the inside only. Suitable for most hot and cold foods, salads, and noodles.

- 2PE (Double Poly): Coating on both the inside and outside. This is crucial for cold foods stored in refrigerators or freezers, as it prevents condensation from softening the paper from the outside.

- Performance: Excellent grease and moisture resistance. Heat sealable, ensuring leak-proof corners.

PLA (Polylactic Acid) Lining

For brands targeting a strictly “plastic-free” narrative, PLA is a bioplastic derived from renewable resources like corn starch.

- Pros: Industrially compostable. Functions similarly to PE in terms of moisture resistance.

- Cons: Lower heat tolerance than PE (typically up to 40-50°C, though high-heat formulations exist). More expensive than standard PE.

Aqueous (Water-Based) Coatings

A newer innovation, aqueous coatings are painted onto the paper like ink. They provide grease resistance without a separate plastic film layer.

- Pros: Fully recyclable in standard paper streams.

- Cons: Generally offers lower barrier performance compared to PE/PLA. Best for foods that are not extremely wet or oily.

3. Structural Designs and Mechanisms

The physical design of the container dictates how easy it is to pack, stack, and consume from. When working with a paper lunch containers manufacturer, consider these structural elements.

Tapered vs. Straight Walls

Most paper lunch containers feature tapered walls (wider at the top than the bottom). This design allows empty containers to nest inside each other, drastically reducing shipping volume and storage space requirements. Straight-walled boxes often require assembly or take up significantly more space.

Locking Mechanisms

- Tab Lock: A simple flap that tucks into a slot. Easy to open and close. Good for dry foods or short transport.

- Webbed Corners (Leak-Proof): The paper is folded rather than cut at the corners, creating a continuous basin. This is mandatory for curries, sauces, and dressed salads.

- Interlocking Flaps: Provides a more secure closure for delivery, reducing the risk of accidental opening.

Window Patching

Adding a clear window allows customers to see the product, which is vital for grab-and-go retail environments. Windows can be made from PET (standard plastic) or PLA (compostable) to match the lining of the box.

4. Sizing Guide: Matching Capacity to Menu

Choosing the right size is about portion control and presentation. A container that is too large makes the portion look small; one that is too small causes spills. Capacities are often quoted in fluid ounces (oz) or milliliters (ml).

| Common Size | Approx. Volume | Typical Dimensions (L x W x H) | Best Use Cases |

|---|---|---|---|

| Small (No. 1) | 26 oz / 750 ml | 130 x 105 x 65 mm | Side dishes, small salads, rice portions, nuggets. |

| Medium (No. 8) | 45 oz / 1300 ml | 160 x 120 x 65 mm | Standard meals, pasta, stir-fry, burger + fries combo. |

| Large (No. 3) | 66 oz / 1900 ml | 215 x 160 x 48 mm | Family packs, large salads, catering platters. |

| Deep/Tall | 32 oz / 1000 ml | Round bottom or tall square | Soups, noodle dishes requiring vertical space. |

Note: Dimensions vary slightly by manufacturer. Always request a physical sample to test with your actual menu items.

5. Customization and Branding

Custom printed paper lunch containers are a mobile billboard for your brand. When moving from generic stock to custom packaging, consider the printing method.

Flexographic Printing

Flexo is the standard for high-volume packaging. It uses flexible relief plates.

- Best for: Simple logos, 1-4 colors, high volume orders.

- Cost: Lower per-unit cost, but requires initial plate setup fees.

Offset Printing (Lithography)

Offset printing produces photographic quality images.

- Best for: Complex artwork, gradients, high-end branding.

- Cost: Higher setup and unit costs, typically requires higher MOQs (Minimum Order Quantities).

Artwork Preparation Checklist

To ensure a smooth production process with your supplier:

- Vector Files: Supply logos in AI, EPS, or PDF format.

- Pantone Codes: Specify PMS (Pantone Matching System) codes for exact color consistency.

- Safe Zones: Ensure text and logos are within the “safe zone” of the dieline to avoid being cut off or folded over.

6. Use Case Scenarios: Choosing the Right Container

Scenario A: Hot, Greasy Food (Fried Chicken, Burgers)

Challenge: Grease penetration and steam accumulation making food soggy.

Solution: Use a Kraft container with a strong PE lining. Consider ventilation holes (steam vents) to allow moisture to escape, keeping the food crispy. A higher GSM (320+) is recommended to resist grease saturation.

Scenario B: Cold Salads and Poke Bowls

Challenge: Dressing leakage and condensation.

Solution: A container with a window is excellent for display. If the salad is pre-packed and refrigerated, a double poly (2PE) coating is essential to prevent the box from absorbing moisture from the outside air (condensation).

Scenario C: Saucy Dishes (Curries, Pasta)

Challenge: Leakage at the corners.

Solution: Requires a “folded corner” or webbed design rather than glued tabs. The interior must be poly-coated. Round-bottom paper bowls are often preferred over square boxes for soups and curries as they eliminate corners entirely.

7. Manufacturing and Quality Assurance

Reliable paper lunch containers suppliers employ rigorous quality control measures. When evaluating a potential partner, inquire about their testing protocols.

Key Quality Tests

- Grease Resistance Test (Kit Test): Measures how long the paper resists oil penetration.

- Water Absorption (Cobb Test): Determines the water absorption capacity of the paper surface.

- Load Bearing Test: Ensures the bottom of the container won’t fall out when filled with hot, heavy food.

- Odor Test: Ensures the paper and ink do not impart any smell to the food (critical for hot food).

8. Buying Guide: Procurement and Logistics

Navigating the supply chain requires understanding the balance between cost, volume, and lead time.

Minimum Order Quantities (MOQ)

For custom printed items, MOQs are necessary to cover machine setup times.

- Small Run: 5,000 – 10,000 units. Higher price per unit, good for market testing.

- Standard Run: 30,000 – 50,000 units. Optimal price-performance ratio.

- High Volume: 100,000+ units. Lowest unit cost, requires significant storage space.

Lead Times

Production time is distinct from shipping time.

- Sampling: 7–10 days for a custom printed sample.

- Mass Production: Typically 15–25 days after artwork approval.

- Shipping: Sea freight is the most economical for bulk packaging but takes 4–6 weeks. Air freight is prohibitively expensive for low-value, high-volume items like boxes.

Storage Considerations

Paper is hygroscopic (absorbs moisture). Warehousing must be dry and ventilated. Cartons should be stored off the ground on pallets to prevent moisture absorption from the floor, which can cause boxes to warp or mold.

9. Sustainability and Compliance

As regulations tighten globally, understanding compliance is mandatory. Ensure your supplier uses FDA-approved or food-grade certified materials. If claiming “compostable,” verify that the specific lining (like PLA) meets standards such as ASTM D6400 or EN 13432. Avoid vague greenwashing terms; stick to verifiable material facts.

Frequently Asked Questions (FAQ)

1. Can paper lunch containers be used in the microwave?

Generally, yes. Paper is microwave-safe. However, containers with standard PE linings are safe for reheating but not for cooking at high temperatures. Containers with foil stamping or metallic inks are not microwave safe.

2. What is the difference between “biodegradable” and “compostable”?

Biodegradable is a broad term meaning it will eventually break down, but it could take years. Compostable means it breaks down into non-toxic organic matter within a specific timeframe under specific conditions (usually industrial composting).

3. How do I prevent the containers from getting soggy with hot food?

Choose a container with a high-quality PE or PLA lining and adequate paper thickness (300gsm+). For fried foods, ensure the design includes steam vents to release moisture.

4. Can I print on the inside of the container?

Printing on the inside requires special food-safe, odorless inks and often an over-varnish or coating to prevent ink migration. It is more expensive and technically complex but possible for high-end branding.

5. Why is the MOQ for custom printing higher than plain stock?

Custom printing requires making specific printing plates and setting up the production line for your unique design. The setup cost and time make small runs economically unviable for the manufacturer.

6. How do I measure a paper lunch box correctly?

Measure the top length and width, the bottom length and width, and the vertical height. Since most boxes are tapered, top and bottom dimensions will differ. Volume is the most accurate metric for food capacity.

7. Are brown Kraft boxes more sustainable than white ones?

Not necessarily. While brown Kraft uses unbleached pulp (fewer chemicals), both can be sourced from sustainable forests. The lining (plastic vs. bio) is usually the bigger factor in overall sustainability.

Conclusion: Elevating Your Food Service Brand

Selecting the right paper lunch container is a balance of science, art, and logistics. It requires understanding the chemical properties of coatings, the structural engineering of the fold, and the visual impact of the print. By partnering with a knowledgeable paper lunch containers supplier, you can secure packaging that not only protects your food but also enhances your customer’s experience and supports your brand’s operational goals.

Whether you need a grease-resistant solution for fried chicken or a sleek, windowed box for salads, the right specification is out there. Take the time to request samples, test them with your specific menu items, and plan your inventory to avoid disruptions.

Ready to upgrade your food packaging?

At YBJ Packing, we specialize in high-quality, custom-engineered food packaging solutions for global buyers. From material selection to final logistics, our team is here to guide you.

Request a Quote today or visit our How to Order page to start your custom project.