In the competitive landscape of food service and retail, packaging serves two critical roles: protecting the product and projecting the brand. For businesses handling hot foods, fresh produce, or ready-to-eat meals, Polypropylene (PP) has emerged as the material of choice. Unlike standard plastics, PP offers a unique combination of heat resistance, durability, and food safety compliance.

Sourcing custom plastic PP packaging boxes wholesale is a strategic move for restaurant chains, food distributors, and packaging procurement officers. It allows for significant cost reduction while enabling tailored branding that stands out on the shelf or at the customer’s doorstep. However, navigating the technical specifications—from material thickness to printing methods—can be complex.

This comprehensive guide explores everything B2B buyers need to know about ordering custom PP packaging. We will cover technical properties, customization possibilities, quality control, and the logistics of bulk ordering.

Why Polypropylene (PP) is the Gold Standard for Food Packaging

Polypropylene (Resin Identification Code 5) is widely regarded as one of the safest and most versatile plastics for food contact. Understanding its properties helps in making informed procurement decisions.

Thermal Resistance and Microwave Safety

The primary advantage of PP over other plastics like PET (Polyethylene Terephthalate) or PVC (Polyvinyl Chloride) is its high melting point. PP packaging can typically withstand temperatures ranging from approximately -20°C to 120°C (-4°F to 248°F). This makes it the industry standard for:

- Microwavable meal prep containers: Customers can reheat food directly in the box without warping or chemical leaching.

- Hot fill applications: Suitable for soups, sauces, and freshly cooked entrees.

- Freezer-to-microwave convenience: PP does not become brittle at freezing temperatures as easily as some other polymers, provided the correct impact modifiers are used.

Chemical Resistance and Grease Barriers

Food products often contain oils, acids (like vinegar or citrus), and salts that can degrade lesser quality packaging. PP is highly resistant to fats and organic solvents. This ensures that a plastic PP packaging box maintains its structural integrity and does not absorb stains or odors, keeping the food fresh and the presentation clean.

Durability and Impact Strength

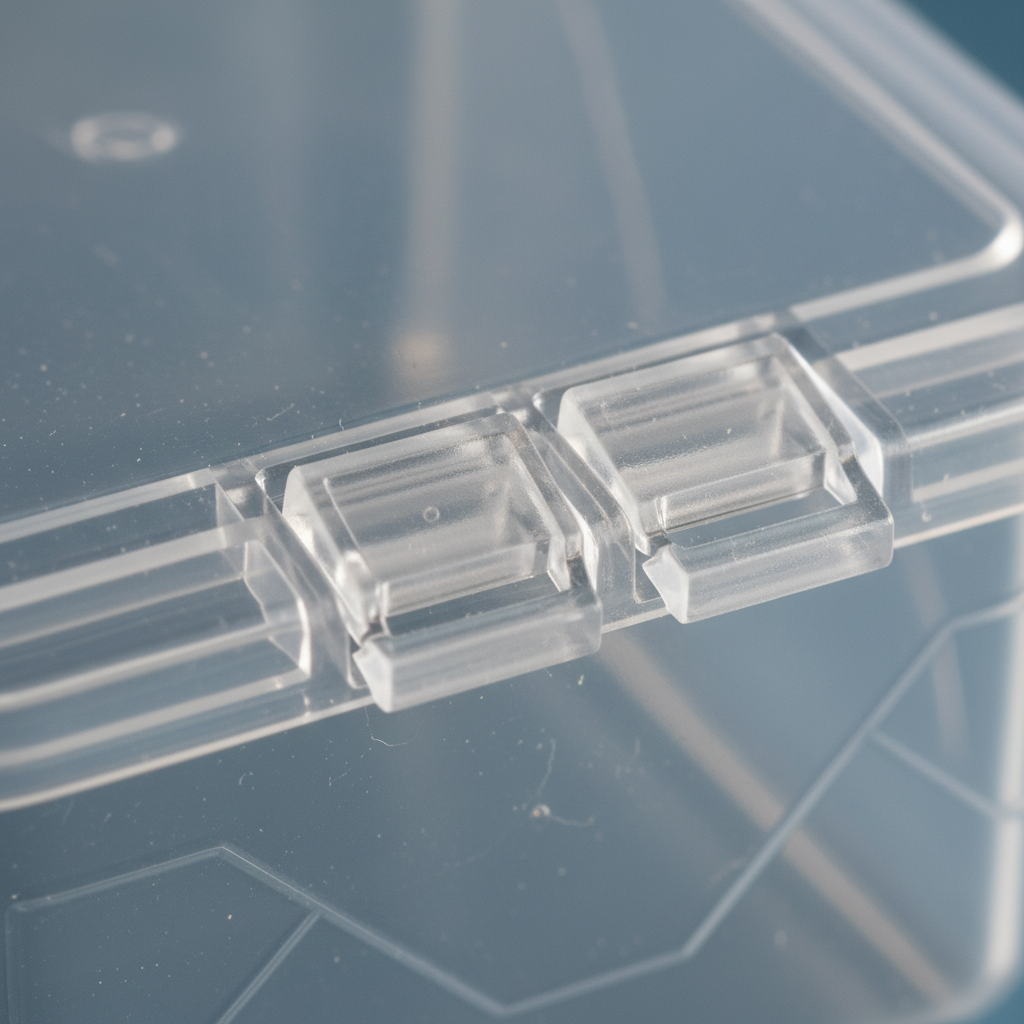

For wholesale buyers shipping products across long distances, durability is non-negotiable. PP is a “tough” plastic. It has excellent fatigue resistance, meaning it can withstand stress without cracking. This is particularly important for containers with “living hinges” (where the lid is connected to the base by a thin web of plastic), a common design in clamshell takeout boxes.

Types of Custom Plastic PP Packaging Boxes

When ordering wholesale, you are not limited to a single style. Manufacturers offer various form factors depending on the product application.

1. Thermoformed Clamshells and Trays

These are created by heating a sheet of PP and molding it over a tool. They are cost-effective for high-volume orders.

- Best for: Takeout meals, deli counters, and fresh produce.

- Features: often include snap-locks, leak-resistant seals, and ribbed walls for strength.

2. Die-Cut Folding Cartons

Similar to paper boxes but made of translucent or opaque PP sheets. These are creased and die-cut, shipped flat, and assembled by the user.

- Best for: Retail merchandising, gift sets, and confectionery.

- Features: High clarity options, easy to print on, space-saving during shipping (flat-packed).

3. Injection Molded Containers

Made by injecting molten PP into a steel mold. These are thicker, more rigid, and reusable.

- Best for: Premium meal prep services, heavy items, and reusable container programs.

- Features: superior wall thickness, airtight lids, and high perceived value.

Printing and Customization Options

Branding is a primary driver for custom packaging. Printing on plastic requires specialized techniques to ensure ink adhesion and vibrancy. Here are the standard options for food packaging boxes.

Offset Printing (Lithography)

Offset printing is ideal for high-volume orders of folding PP cartons. It delivers high-resolution images and precise color matching (CMYK + Pantone).

- Pros: Photo-quality gradients, cost-effective at scale.

- Cons: High setup costs make it unsuitable for small runs.

UV Silk Screen Printing

This method pushes ink through a mesh screen onto the plastic surface. UV curing ensures the ink dries instantly and adheres strongly.

- Pros: Thick, vibrant ink deposits; excellent durability; tactile feel.

- Cons: Not suitable for complex gradients or photographic images; usually limited to 1-4 spot colors.

Flexographic Printing

Commonly used for flexible packaging and thermoformed cups/bowls. It uses flexible relief plates.

- Pros: Very fast production speeds; good for simple logos and patterns.

- Cons: Lower resolution compared to offset.

Embossing and Debossing

For a premium, subtle look, logos can be molded directly into the plastic (embossed raised or debossed recessed) during the thermoforming or injection molding process.

- Pros: Permanent branding without ink; adds structural rigidity.

- Cons: Requires custom tooling (molds), which increases upfront costs.

Special Finishes

- Matte/Frost Effect: Gives a sophisticated, soft-touch look and hides fingerprints.

- Gloss Lamination: Enhances color vibrancy and shine.

- Hot Foil Stamping: Adds metallic gold or silver accents (requires specialized surface treatment on PP).

Technical Specifications Checklist

When submitting a Request for Quotation (RFQ) to a manufacturer, precision is key. Use this checklist to define your requirements.

| Specification | Details to Consider |

|---|---|

| Material Thickness | Measured in microns or mil. Folding boxes: 0.3mm–0.8mm. Thermoformed trays: 0.4mm–1.0mm. Thicker = stronger but more expensive. |

| Dimensions | Length x Width x Depth. Specify if these are internal (usable space) or external dimensions. |

| Color/Opacity | Clear, frosted, solid white, solid black, or custom Pantone color match. |

| Closure Mechanism | Tab-lock, auto-lock bottom, snap-fit lid, or heat-sealable rim. |

| Ventilation | Do you need vent holes for steam release (hot foods) or air circulation (produce)? |

| Surface Treatment | Corona treatment is often required for printing on PP to ensure ink adhesion. |

Manufacturing and Quality Control

Understanding the manufacturing process helps in managing lead times and quality expectations.

The Production Workflow

- Design & Prototyping: CAD drawings are created. A 3D printed or handmade sample is produced for size verification.

- Tooling (Molds): For thermoforming or injection molding, metal molds are machined. This is the longest lead-time stage (1–3 weeks).

- Extrusion: Raw PP resin pellets are melted and extruded into sheets.

- Forming/Cutting: The sheets are either vacuum-formed into shapes or die-cut into folding box templates.

- Printing: Sheets are printed before cutting (for folding boxes) or containers are dry-offset printed after forming.

- Quality Assurance (QA): Random sampling checks for wall thickness consistency, print registration, and closure functionality.

Key Quality Tests for Food Packaging

- Migration Testing: Ensures chemicals do not transfer from the plastic to the food (critical for regulatory compliance).

- Leak Testing: Essential for sauce containers and soups.

- Drop Test: Simulates logistics handling to ensure boxes don’t crack upon impact.

- Stacking Strength: Verifies that boxes won’t collapse when palletized.

Buying Guide for Wholesale Orders

Procuring custom packaging involves more than just picking a product. Here is how to navigate the ordering process effectively.

Minimum Order Quantities (MOQ)

Customization requires setup. Manufacturers typically set MOQs to amortize the setup costs (machine calibration, plate making, mixing inks).

- Standard items: Lower MOQs (e.g., 1,000–5,000 units).

- Custom size/print: Higher MOQs (e.g., 10,000–50,000 units) are common to achieve a viable unit price.

Artwork and File Preparation

To avoid delays, ensure your design team provides vector files (AI, PDF, EPS). Raster images (JPG, PNG) are usually insufficient for high-quality packaging printing. Always request a digital proof (dieline) before mass production begins.

Lead Times and Logistics

Custom manufacturing is not instant. Typical timelines might look like this:

- Sample approval: 5–10 days.

- Mass production: 15–25 days (depending on quantity and complexity).

- Shipping: Sea freight is cost-effective for bulk but takes weeks. Air freight is fast but expensive.

Tip: PP boxes can be bulky. For folding cartons, they ship flat, saving massive amounts of freight cost. Thermoformed bowls do not fold, so calculate the “volume weight” carefully.

Sustainability and End-of-Life

Modern buyers are environmentally conscious. Polypropylene is a recyclable material (Code 5). Unlike mixed-material packaging, pure PP boxes are easier to process in recycling streams. When marketing your product, highlight the reusability of the container (e.g., “Dishwasher Safe” and “Microwave Safe”), which encourages consumers to reuse the box at home rather than discarding it immediately, extending the product’s lifecycle.

Common Use Cases for Custom PP Boxes

1. Bento and Meal Prep

Compartmentalized PP trays are the industry standard for meal prep services. They separate proteins from sides, preventing sogginess, and are ready for the microwave.

2. Bakery and Confectionery

Clear PP folding boxes are excellent for macarons, cupcakes, and cookies. The high clarity allows the product to be the star, while the material keeps moisture out, preserving freshness.

3. Hot Food Delivery

With the rise of food delivery apps, restaurants need packaging that retains heat. PP containers with vented lids prevent food from steaming itself soggy while keeping it warm during transport.

How to Choose the Right Supplier

Selecting a partner for your plastic PP packaging box wholesale needs involves vetting their capabilities.

- Experience: Do they specialize in food-grade packaging?

- Customization Capability: Can they handle the specific printing method you require?

- Sample Policy: Will they provide a physical sample before the full run?

- Responsiveness: clear communication is vital for custom projects.

If you are ready to explore options or need guidance on the right specs for your food product, visiting a dedicated manufacturer’s contact page is the first step.

Frequently Asked Questions (FAQ)

1. Is PP packaging safe for all types of food?

Yes, food-grade PP is safe for acidic, oily, and hot foods. It is non-toxic and does not contain BPA (Bisphenol A) in its standard formulation.

2. Can I put custom PP boxes in the freezer?

Standard PP can become brittle at very low temperatures. If you need deep-freeze capability (below -20°C), inform your supplier so they can use a copolymer PP blend designed for freezer impact resistance.

3. What is the difference between PP and PET?

PET is clearer (like a water bottle) but has poor heat resistance and will warp in a microwave. PP is slightly hazier (naturally frosted) but has excellent heat resistance. Choose PP for hot food and PET for cold deli items.

4. How do I get a quote for a custom size?

You will need to provide the internal dimensions, desired material thickness, estimated quantity, and artwork details. Visit our how to order page for a step-by-step guide.

5. Why is the MOQ higher for custom printing?

Printing involves creating custom plates and setting up the press, which consumes material and time. Spreading this fixed cost over a small number of units would make the price per box prohibitively high.

6. Are PP boxes waterproof?

Yes, PP is impermeable to water. However, the “leak-proof” nature of the box depends on the closure design (lid fit), not just the material.

7. Can PP boxes be recycled?

Yes, PP is a widely recycled plastic (Number 5). Check local municipal guidelines, but generally, rigid PP containers are accepted in many curbside programs.

Conclusion

Investing in custom plastic PP packaging is a smart decision for B2B food buyers looking for reliability, safety, and brand impact. Its ability to handle heat, resist grease, and protect food during transit makes it superior to many alternatives. By understanding the specifications—from micron thickness to printing techniques—you can communicate effectively with manufacturers and secure the best packaging for your products.

Ready to upgrade your food packaging? Request a quote today to discuss your specific requirements and get a custom solution tailored to your brand.