Introduction: The Strategic Value of High-Quality Greaseproof Packaging

In the competitive landscape of the food service industry, packaging serves two critical roles: protecting the integrity of the food and acting as a mobile billboard for the brand. For procurement managers, restaurant chains, and food distributors, sourcing the right custom greaseproof paper bags is not merely a purchasing task—it is an operational necessity.

Greaseproof paper bags are engineered to resist oil and fat penetration, ensuring that fried foods, pastries, and sandwiches remain appetizing while preventing unsightly stains on customers’ hands or clothing. However, not all greaseproof paper is created equal. The market offers a vast array of specifications, from varying GSM (grams per square meter) weights to distinct coating technologies and “Kit levels” of grease resistance.

This comprehensive guide explores the technical specifications, printing options, and wholesale ordering considerations for custom greaseproof paper bags. Whether you are scaling a franchise or sourcing for a distribution network, understanding these nuances will help you make informed decisions that balance cost, performance, and brand impact.

Understanding Greaseproof Technology: How It Works

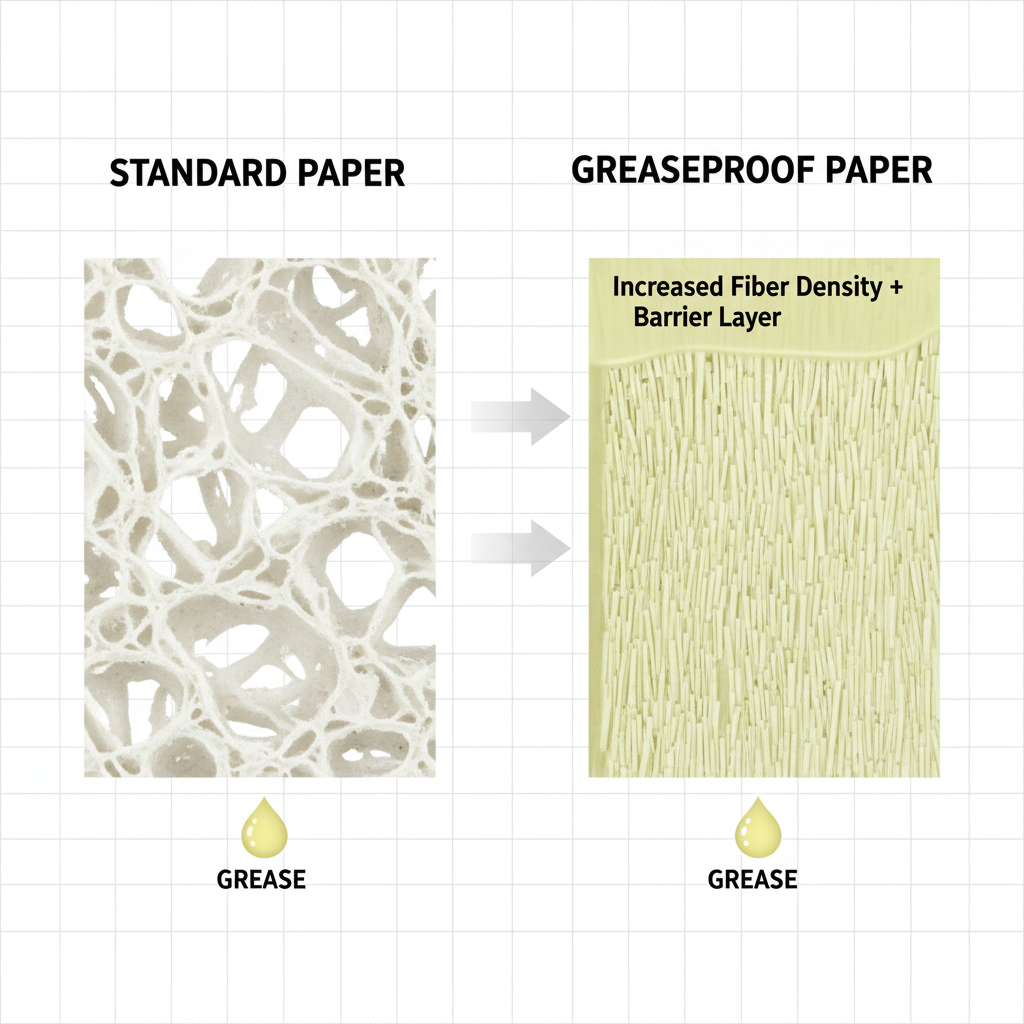

Before selecting a bag, it is essential to understand the mechanism behind grease resistance. Standard paper is porous; without treatment, oils from food (like fries or buttery pastries) are absorbed into the fibers, causing the paper to become translucent and weak. Greaseproof paper addresses this through one of two primary methods:

1. Mechanical Refining (Natural Greaseproof)

In this process, the paper pulp is beaten extensively during manufacturing. This breaks down the fibers to a point where they bond extremely tightly, reducing the porosity of the sheet. This creates a dense, low-permeability surface without the need for chemical coatings. These papers are often referred to as “parchment” or naturally greaseproof papers. They are typically breathable, which keeps crispy foods crunchy rather than soggy.

2. Chemical Treatment and Coatings

Alternatively, paper can be treated with sizing agents or coatings (such as PE – Polyethylene or wax) to create a barrier. While PE coatings offer a complete moisture and grease barrier, they can impact the recyclability of the product depending on local facilities. For many modern applications, fluorochemical-free treatments are becoming the standard to meet environmental regulations while maintaining high performance.

The “Kit Level” Standard

In the paper industry, grease resistance is often measured by the “Kit Test” (TAPPI T 559). This test rates the paper on a scale from 1 to 12 based on its resistance to aggressive oil mixtures.

- Kit Level 1-3: Low resistance. Suitable for dry goods or items with very low fat content (e.g., bread loaves).

- Kit Level 4-6: Medium resistance. Ideal for cookies, muffins, and standard bakery items.

- Kit Level 7-9: High resistance. Required for fried foods, french fries, and oily sandwiches.

- Kit Level 10-12: Maximum resistance. Used for extremely oily industrial applications or long-duration storage of high-fat foods.

When you browse our food packaging bag options, knowing your required Kit Level ensures you don’t overpay for unnecessary specs or under-spec a bag that fails in the customer’s hands.

Material Specifications: Choosing the Right Substrate

Selecting the base material is the first step in customization. The choice impacts the bag’s look, feel, and price point.

White vs. Brown Kraft Greaseproof

- Brown Kraft (Natural): Offers a rustic, eco-friendly aesthetic. It is popular with organic brands, artisan bakeries, and farm-to-table concepts. Brown kraft is excellent for hiding minor grease spots that might appear over time.

- White Bleached Kraft: Provides a clean, clinical look and serves as a superior canvas for vibrant, full-color printing. If your branding relies on bright yellows, light blues, or intricate gradients, white paper ensures color accuracy.

GSM (Grammage) Guidelines

The thickness of the paper is measured in GSM. Choosing the right weight is a trade-off between cost and durability.

- 30-40 GSM: Very thin. Typically used for light wrapping sheets or small, single-pastry bags.

- 40-50 GSM: Standard industry weight for burger bags, fry bags, and sandwich bags. It offers enough rigidity to hold shape but remains cost-effective.

- 60+ GSM: Heavy-duty. Used for larger takeaway sacks or bags that need to hold heavier items without tearing.

Bag Styles and Structural Engineering

The physical construction of the bag dictates how easy it is to load in a fast-paced kitchen and how it presents the food.

1. Flat Bags (V-Shape)

These are simple, two-dimensional bags with no gussets. They are the most economical option.

- Best for: Cookies, pretzels, flat sandwiches, pancakes.

- Pros: Lowest cost, minimal storage space.

- Cons: Limited volume capacity.

2. Satchel Bags (Side Gusset)

Satchel bags feature expandable pleats (gussets) on the sides but typically have a pinched bottom.

- Best for: Baguettes, multiple pastries, thick sandwiches.

- Pros: Expands to fit bulky items; easier to load than flat bags.

3. SOS Bags (Self-Opening Sack / Square Bottom)

These bags have a flat, rectangular bottom that allows them to stand upright on a counter.

- Best for: Takeout meals, lunch orders, bulk bakery items.

- Pros: Premium presentation, stands independently for easy loading, high capacity.

- Cons: Higher manufacturing cost compared to flat bags.

4. Window Bags

A hybrid option incorporating a clear film (plastic or PLA) window into the greaseproof paper.

- Best for: Display counters where product visibility drives sales (donuts, artisan breads).

- Note: Ensure the film material aligns with your sustainability goals.

Printing and Customization Options

Custom printing is where a generic commodity becomes a brand asset. When ordering wholesale greaseproof bags, you generally have two main printing technologies available.

Flexographic Printing (Flexo)

Flexo is the industry standard for high-volume packaging. It uses flexible relief plates to transfer ink onto the paper.

- Suitability: Ideal for simple logos, patterns, and text in 1-4 spot colors.

- Cost: Lower unit cost for high volumes; initial setup (plate) fees apply.

- Inks: typically water-based or soy-based, which are food-safe and eco-friendly.

Offset Printing

Offset printing is used for high-definition imagery and complex gradients.

- Suitability: Photo-realistic designs or complex artwork.

- Cost: Higher setup and running costs; generally reserved for premium product lines.

Food-Safe Inks

Regardless of the printing method, safety is paramount. Ensure your supplier uses inks that comply with international food safety standards (such as FDA or EU regulations). Water-based inks are preferred as they do not emit Volatile Organic Compounds (VOCs) and are odorless, ensuring the smell of the ink does not taint the food.

Wholesale Buying Guide: Ordering Logistics

Navigating the procurement process requires attention to Minimum Order Quantities (MOQs), lead times, and logistics. Here is a checklist for buyers.

1. Minimum Order Quantity (MOQ)

Custom manufacturing requires machine setup, plate mounting, and calibration. Consequently, factories set MOQs to make the run viable.

- Standard MOQ: Often starts around 10,000 to 30,000 units depending on the size and complexity of the print.

- Price Breaks: Unit costs drop significantly at higher volumes (e.g., 100,000+ units) due to manufacturing efficiencies.

2. Lead Times

Plan ahead. Custom packaging is not an off-the-shelf purchase.

- Design & Approval: 3-7 days.

- Production: 15-30 days (depending on factory load).

- Shipping: Variable based on location and method (sea freight vs. air freight).

If you have a strict deadline, such as a store opening or a seasonal promotion, contact our team early to discuss expedited options.

3. Artwork Preparation

To avoid delays, ensure your design files are print-ready:

- Format: Vector files (AI, PDF, EPS) are required for crisp lines.

- Colors: Specify Pantone (PMS) codes to ensure brand color consistency.

- Bleed: If your design runs to the edge of the bag, include appropriate bleed margins.

Sustainability Considerations

Modern consumers are increasingly conscious of packaging waste. When selecting greaseproof bags, consider the end-of-life scenario.

- Recyclable: Uncoated, naturally greaseproof papers are generally recyclable in standard paper streams.

- Compostable: Papers treated with bio-waxes or uncoated papers can often be certified compostable.

- PE Coated: While effective, traditional plastic coatings can make recycling difficult. If sustainability is a core brand value, ask about aqueous coatings or PLA linings.

Quality Assurance: What to Look For

When you receive your shipment or a pre-production sample, perform these checks:

- The Oil Test: Place a sample of your greasiest food product in the bag and leave it for 30 minutes. Check the exterior for spotting.

- The Rub Test: Rub the printed area with a dry tissue and then a slightly damp tissue to ensure the ink does not smudge or transfer.

- Seam Strength: Pull gently on the glued seams (side and bottom) to ensure they do not pop open under stress.

- Odor Check: The bag should smell like paper, not chemicals. Strong chemical odors indicate poor quality ink or curing processes.

Common Use Cases and Recommended Specs

Fast Food & Fried Chicken

- Requirement: High grease resistance (Kit 7+), heat retention.

- Recommended: 50 GSM White Kraft, SOS style or Satchel.

Artisan Bakery (Croissants, Pastries)

- Requirement: Breathability (to maintain flake), medium grease resistance (Kit 4-5).

- Recommended: 40 GSM Brown Kraft, Window bag or Flat bag.

Deli & Sandwiches

- Requirement: Moisture resistance (for sauces/mayo), moderate grease resistance.

- Recommended: PE-coated paper or Wax-treated paper, Satchel style.

Frequently Asked Questions (FAQ)

1. Can I print on both sides of the greaseproof bag?

Yes, double-sided printing is possible. However, most brands opt for full coverage on the exterior. Printing on the interior is generally avoided for direct food contact safety, unless specific food-safe barriers are applied over the ink.

2. What is the difference between greaseproof and wax paper?

Greaseproof paper is typically chemically treated or mechanically refined to resist oil permeation and can withstand higher temperatures. Wax paper is coated with paraffin or soybean wax; while it resists grease and moisture, it cannot be used in ovens as the wax will melt. Greaseproof paper is generally more versatile for hot foods.

3. How do I determine the right size for my product?

Measure your food item (Length x Width x Height). Add 1-2 cm of clearance to the width and depth for easy loading. For height, add enough space to fold the bag closed if required (usually 3-5 cm). We recommend requesting samples to test fit before placing a bulk order.

4. Are custom greaseproof bags microwave safe?

Standard uncoated greaseproof paper is usually microwave safe. However, bags with metallic inks (gold/silver foil) or specific plastic coatings may not be. Always specify if the bag needs to be microwaveable during the ordering process.

5. What is the shelf life of these bags?

Paper bags have a long shelf life if stored correctly. They should be kept in a cool, dry place away from direct sunlight and humidity. High humidity can cause the paper to curl or the glues to weaken over extended periods (1+ years).

6. Can you help with the design if I only have a logo?

Yes, many manufacturers, including YBJ Packing, offer design assistance. If you provide a high-resolution logo and guidance on placement, the pre-press team can create a digital mockup for your approval. Visit our how to order page for more details on the design workflow.

7. Why is my bag leaking grease despite being “greaseproof”?

This usually indicates the “Kit Level” is too low for the food type, or the food is extremely hot and breaking down the resistance. Alternatively, the grease might be leaking through the seams rather than the paper itself. Upgrading to a higher GSM or a folded-bottom construction usually solves this.

Conclusion

Sourcing custom greaseproof paper bags wholesale is a balance of science and art. It requires understanding the technical demands of your menu items—grease levels, temperature, and moisture—and marrying them with impactful branding that resonates with your customers.

By choosing the right material, size, and print finish, you elevate the customer experience from a simple transaction to a premium interaction. Whether you need a rustic brown kraft bag for a bagel shop or a high-gloss, branded sack for a burger chain, the options are extensive.

Ready to upgrade your food packaging?

At YBJ Packing, we specialize in high-quality, custom-printed food service solutions. Request a quote / Get a sample today, and let our team help you engineer the perfect bag for your business.