Introduction: The Strategic Value of Premium Burger Packaging

In the highly competitive food service industry, the burger remains a universal staple. However, the difference between a memorable dining experience and a forgettable meal often extends beyond the recipe—it lies in the presentation and preservation of the food. For B2B buyers, including restaurant chains, food distributors, and procurement managers, sourcing custom burger packaging boxes wholesale is not just a logistical necessity; it is a strategic branding decision.

Packaging serves two critical roles: protecting the product integrity during transit and acting as a mobile billboard for your brand. A soggy bun or a crushed box can ruin customer perception instantly. Conversely, a sturdy, grease-resistant, and beautifully printed box enhances perceived value and encourages social media sharing. This comprehensive guide explores the technical specifications, material choices, printing technologies, and purchasing strategies necessary to source high-quality burger boxes that align with your operational needs and budget.

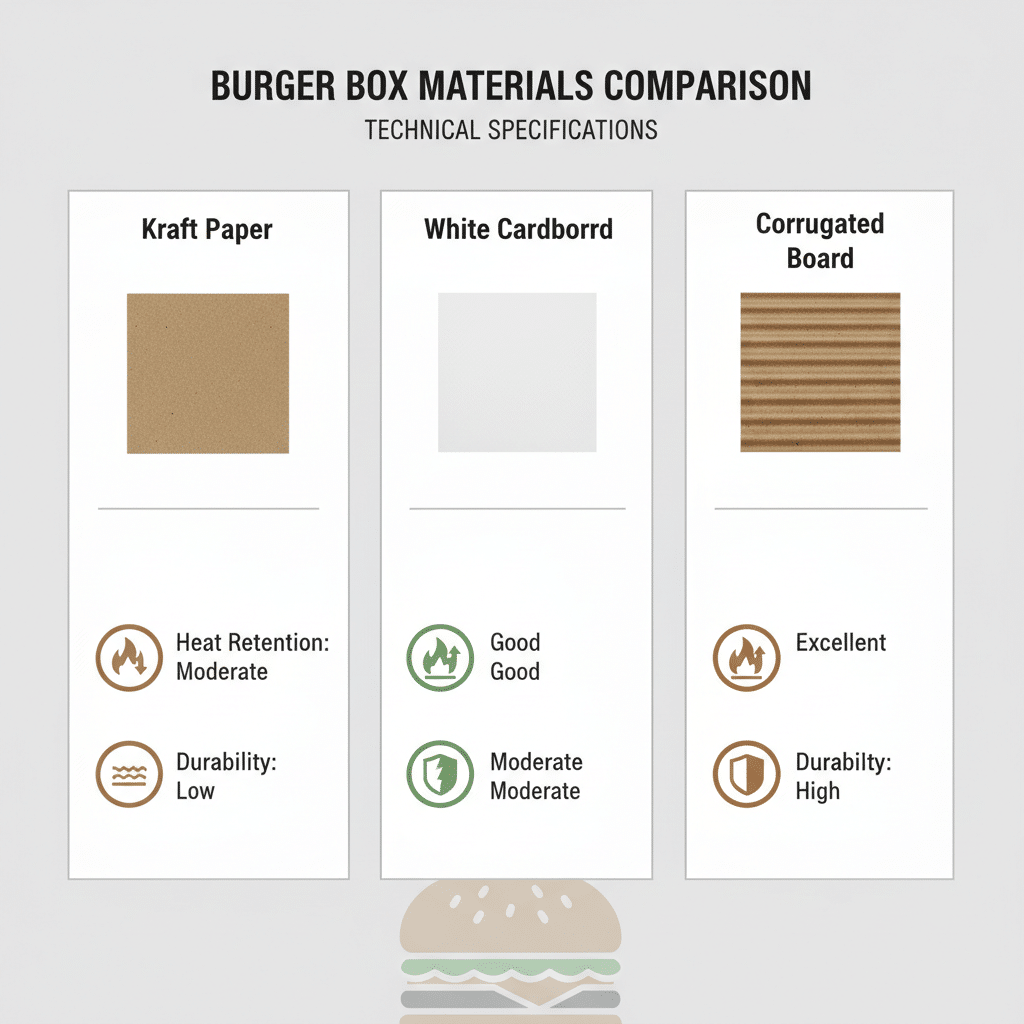

1. Key Material Options for Burger Boxes

Choosing the right substrate is the foundation of effective packaging. The material determines the box’s strength, insulation properties, and printability. Here are the primary materials used in industrial food packaging manufacturing.

Food-Grade Kraft Paper (Brown)

Kraft paper is a dominant choice for brands aiming for an organic, eco-friendly aesthetic. Unbleached and naturally brown, it signals sustainability to the consumer.

- Pros: High tear resistance, natural look, often made from recycled fibers, cost-effective.

- Cons: Colors printed on brown backgrounds may appear darker or less vibrant; requires white ink under-printing for bright logos.

- Best For: Fast-casual chains, organic burger brands, and food trucks prioritizing a rustic vibe.

Ivory Board / White Cardboard (SBS)

Solid Bleached Sulfate (SBS) or ivory board provides a pristine white surface both inside and out. It is the standard for premium printing.

- Pros: Superior print quality (colors pop), smooth texture, hygienic appearance.

- Cons: Slightly higher cost than standard Kraft; shows grease stains more visibly if not properly coated.

- Best For: Premium gourmet burgers, brands with complex or colorful graphics, and franchise chains requiring strict color matching.

Corrugated Board (E-Flute or F-Flute)

For delivery-heavy business models, standard cardstock may not suffice. Corrugated board consists of a fluted layer sandwiched between two liners.

- Pros: Excellent thermal insulation (keeps burgers hot), superior crush resistance, stackable.

- Cons: Thicker material takes up more storage space; slightly rougher print surface compared to SBS (unless litho-laminated).

- Best For: Delivery-only kitchens, heavy gourmet burgers, and large orders where heat retention is critical.

2. Grease Resistance and Coatings: Preventing the “Soggy Bottom”

One of the most common failures in burger packaging is grease leakage. A box that absorbs oil loses structural integrity and stains customers’ hands. Understanding coating options is essential for sourcing reliable burger boxes.

PE (Polyethylene) Coating

This is the industry standard for grease and moisture resistance. A thin layer of plastic is applied to the interior of the paperboard.

- Performance: Excellent against hot grease and sauces.

- Recyclability: Requires specialized recycling facilities to separate the plastic from the paper.

Aqueous Coating

Water-based coatings offer a moderate level of grease resistance. They are often used on the exterior to protect the print but can be formulated for interior food contact.

- Performance: Good for standard burgers; may struggle with extremely juicy or saucy products over long periods.

- Recyclability: Generally fully repulpable and easier to recycle than PE.

PLA (Polylactic Acid) Lining

For brands committed to zero waste, PLA is a bioplastic derived from plant starches (like corn).

- Performance: Comparable to PE for grease resistance.

- Sustainability: Compostable in industrial facilities.

3. Structural Designs and Mechanisms

The structural design affects assembly speed in the kitchen and the eating experience for the customer.

Clamshell Boxes

The classic one-piece design where the lid is hinged to the base.

- Advantages: Quickest to close (vital for high-volume fast food); nests easily to save space.

- Drawbacks: Can sometimes pop open if overfilled; less rigid than tuck-top styles.

Tuck-Top Boxes

These boxes feature a lid that tucks into the front of the box, often with side flaps.

- Advantages: Very secure closure (great for delivery); boxy shape stacks perfectly in delivery bags.

- Drawbacks: Takes a second longer to assemble and close than a clamshell.

Drawer / Sleeve Style

A tray slides into a sleeve. This offers a premium “unboxing” feel.

- Advantages: High perceived value; excellent branding space on the sleeve.

- Drawbacks: Higher cost and slower assembly.

4. Printing Technologies for Custom Branding

When ordering custom food packaging, the printing method impacts cost, quality, and minimum order quantities (MOQs).

Offset Printing (Lithography)

The gold standard for high-quality, photographic imagery. It uses plates to transfer ink to a rubber blanket and then to the paper.

- Quality: Sharpest details, accurate Pantone (PMS) color matching.

- Cost: High setup costs, but very low unit cost for large runs (10,000+).

Flexographic Printing

Uses flexible relief plates. Common for simple logos and patterns on Kraft material.

- Quality: Good for bold lines and text; less ideal for photos.

- Cost: Lower setup costs than offset; efficient for high volumes.

Digital Printing

Direct-to-substrate printing without plates.

- Quality: High detail, good for CMYK designs.

- Cost: Zero setup cost, but higher unit cost. Ideal for short runs, seasonal promos, or market testing.

5. Technical Specifications & Sizing Guide

Specifying the correct size is crucial to prevent product movement (which leads to messy toppings) or crushing. Dimensions are typically measured as Length x Width x Height (L x W x H).

Common Industry Standard Sizes:

- Mini / Slider: 2.5″ x 2.5″ x 2″

- Standard Burger: 4″ x 4″ x 2.5″ or 5″ x 5″ x 3″

- Large / Gourmet: 6″ x 6″ x 3.5″ (Accommodates fries or double patties)

Paper Weight (GSM):

Strength is measured in Grams per Square Meter (GSM).

- 250–300 GSM: Standard for clamshells (lightweight, cost-effective).

- 320–400 GSM: Premium sturdy boxes; recommended for delivery to prevent collapsing under stack weight.

6. The Manufacturing & Quality Assurance Process

Understanding how your boxes are made helps in vetting suppliers. A reliable manufacturer will have strict QC protocols.

Die-Cutting and Creasing

Precision is key. Poorly creased boxes are hard to fold, slowing down your kitchen staff. Ensure your supplier uses high-precision die-cutting molds to ensure every box squares up perfectly.

Gluing

For pre-glued styles (like auto-bottoms or clamshells), the adhesive must be food-safe and heat-resistant. Cheap glues can melt under heat lamps, causing boxes to fall apart.

Food Safety Compliance

Ensure the manufacturer adheres to relevant food contact safety standards (e.g., FDA, EU regulations). This applies to the paperboard, the inks (soy/vegetable-based are preferred), and the coatings.

7. Wholesale Buying Guide: Ordering & Logistics

Navigating the procurement process requires attention to detail to avoid costly mistakes.

Minimum Order Quantities (MOQ)

Custom packaging is an economy of scale game.

- Low MOQ (500–2,000 units): Often digital print. Higher price per unit. Good for startups.

- Standard Wholesale (5,000–10,000+ units): Unlocks offset printing and significantly lower unit costs.

- Container Load: Lowest possible price, but requires warehouse space.

Artwork Preparation

To ensure your brand looks crisp:

- Provide vector files (AI, PDF, EPS).

- Outline all fonts.

- Specify Pantone (PMS) codes if brand colors must be exact.

Lead Times

Factor in:

- Design & Approval: 3–5 days.

- Production: 10–20 days (depending on quantity and complexity).

- Shipping: Air freight (expensive, fast) vs. Sea freight (economical, 30–45 days).

Sampling

Never skip the sample stage.

- Digital Proof: Shows layout and spelling (Free).

- Plain Dummy: Checks size and structure (Low cost).

- Pre-production Sample: Fully printed prototype on actual stock (Higher cost, but essential for large orders).

For details on starting this process, visit our ordering guide.

8. Sustainability and Consumer Trends

Modern consumers are increasingly eco-conscious. Sourcing sustainable packaging is no longer niche—it is expected.

- Recyclable: Ensure coatings do not hinder recycling in your target market.

- Compostable: Look for certifications if marketing as compostable.

- Minimalism: Using less ink and unbleached paper is a growing trend that also reduces costs.

9. Common Use Cases & Scenarios

The Ghost Kitchen

Priority: Heat retention and tamper-evidence.

Recommendation: Corrugated E-flute tuck-top box with a tamper-evident sticker seal.

The Fast Food Franchise

Priority: Speed and cost.

Recommendation: 250 GSM clay-coated clamshell with flexo printing.

The Gourmet Sit-Down (Leftovers)

Priority: Aesthetics and brand reminder.

Recommendation: High-end SBS box with spot UV logo and heavy GSM weight.

10. Frequently Asked Questions (FAQ)

Q1: Can I print on the inside of the burger box?

Yes, inside printing is a great way to reveal a message as the customer eats. However, you must use food-safe, odorless, and migration-free inks (often soy-based) to ensure safety.

Q2: How do I determine the right size for my burger?

Measure your burger fully assembled, including the bun and toppings. Add roughly 0.5 to 1 inch of clearance on all sides to prevent squashing, but don’t make it too big or the burger will slide around.

Q3: What is the difference between CMYK and Pantone printing?

CMYK builds colors using four inks (Cyan, Magenta, Yellow, Black) and is standard for photos. Pantone uses pre-mixed inks for exact color accuracy, which is crucial for consistent brand logos.

Q4: Are custom burger boxes microwave safe?

Paper boxes are generally microwave safe, but metallic finishes (like foil stamping) are not. PE-coated boxes are safe for short reheating, but always confirm specs with your manufacturer.

Q5: How are the boxes shipped?

Wholesale boxes are shipped flat-packed (knocked down) to minimize shipping volume. This significantly reduces freight costs compared to rigid containers.

Q6: Can you help with the dieline design?

Most manufacturers provide a standard dieline template for your graphic designer to use. If you need custom structural adjustments, engineering teams can assist.

Q7: What is the lead time for a custom order?

Typically, production takes 2-3 weeks after artwork approval. Shipping time depends on your location and method (air vs. sea).

Q8: Do you offer eco-friendly greaseproof options?

Yes, water-based (aqueous) coatings and PLA linings are excellent eco-friendly alternatives to traditional PE plastic linings.

Conclusion

Sourcing the right custom burger packaging requires balancing form, function, and finance. From selecting the right GSM weight to choosing between flexo and offset printing, every detail contributes to your brand’s reputation and your bottom line. By partnering with an experienced manufacturer, you can navigate these technical choices with confidence.

Ready to elevate your brand with professional packaging? Contact our team today to discuss your specifications or request a quote for your custom burger boxes.