Introduction to Aluminum Foil Packaging in Food Service

In the competitive landscape of food service and catering, packaging is more than just a vessel; it is a critical component of food safety, temperature maintenance, and brand presentation. For procurement officers, restaurant chain managers, and distributors, selecting the right aluminum foil box is a strategic decision that impacts operational efficiency and customer satisfaction.

Aluminum foil containers and boxes have become a staple in the industry due to their exceptional thermal conductivity, barrier properties against grease and moisture, and versatility in design. Unlike standard paperboard or plastic alternatives, aluminum-laminated packaging offers a unique combination of structural rigidity and aesthetic appeal, often associated with premium takeout or catering services.

This comprehensive guide is designed for B2B buyers navigating the complexities of sourcing aluminum foil box solutions. We will examine material specifications, manufacturing processes, customization options, and the logistical considerations necessary for making informed wholesale purchasing decisions.

1. The Technical Advantage: Why Choose Aluminum Foil Boxes?

Understanding the technical benefits of aluminum foil packaging helps in justifying the investment compared to cheaper alternatives like expanded polystyrene (EPS) or uncoated paper.

Thermal Conductivity and Retention

Aluminum is an excellent conductor of heat. In packaging, this property allows for rapid heating in ovens (where applicable) and, conversely, effective heat retention when the container is sealed. For food delivery services, an aluminum foil box helps maintain the serving temperature of hot meals significantly longer than standard cardboard, especially when paired with a tight-fitting lid.

Barrier Properties

Food-grade aluminum foil provides a total barrier to light, oxygen, moisture, and bacteria. This is crucial for preserving the aroma and freshness of food. In the context of a foil-laminated paper box, the foil layer acts as an impermeable shield, preventing grease from soaking into the paperboard structure. This ensures the box remains rigid and does not collapse or become soggy during transport.

Structural Integrity

When aluminum foil is laminated to paperboard, it creates a composite material that is stronger than either material on its own. The foil adds tensile strength, while the paperboard provides bulk and shape. This composite is capable of supporting heavy, dense foods—such as lasagna, curries, or wet roasts—without buckling.

2. Material Composition and Structure

To order the correct product, buyers must understand the anatomy of an aluminum foil box. It is rarely solid aluminum (which would be a tray); rather, it is usually a multi-layer construction.

The Layers of a Foil Box

- Base Layer (Paperboard): The structural core. Typically made from food-grade virgin wood pulp or high-quality recycled board. The weight usually ranges from 250gsm to 400gsm depending on the box size and required load-bearing capacity.

- Adhesive Layer: A food-safe bonding agent that fuses the foil to the paperboard.

- Barrier Layer (Aluminum Foil): A thin gauge of aluminum (often 6 to 9 microns) is laminated onto the board. It can be applied to the inside (for direct food contact and grease resistance) or the outside (for metallic branding effects), or both.

- Coating (PE/PET): Often, a thin layer of Polyethylene (PE) or Polyethylene Terephthalate (PET) is applied over the foil or on the opposing side to facilitate heat sealing and provide additional liquid resistance.

Material Grades

Ensure your supplier specifies food-grade aluminum (often alloy series 8xxx or 3xxx depending on the foil type). The paperboard should be FDA or EU compliant for direct food contact. Low-quality boards may contain recycled content that is not safe for direct contact with hot, greasy foods, leading to potential migration of contaminants.

3. Types and Configurations of Aluminum Foil Boxes

The market offers various shapes and styles. Choosing the right configuration depends on the menu items and the operational flow of the kitchen.

Standard Rectangular Takeout Boxes

These are the workhorses of the delivery industry. Available in capacities ranging from 500ml to 2000ml, they are stackable and space-efficient.

- Use Cases: Rice dishes, pasta, salads, grilled meats.

- Pros: Easy to stack in delivery bags; standard lid sizes available.

Compartment Boxes (Bento Style)

Foil boxes with built-in dividers or molded compartments are increasingly popular for premium meal sets.

- Use Cases: Corporate catering, airline meals, set menus separating wet and dry ingredients.

- Pros: Prevents flavor cross-contamination; enhances presentation.

Round Bowls and Tubs

While less common in pure foil-laminated board than in solid foil trays, round paper bowls with foil lining are excellent for soups and stews.

- Use Cases: Ramen, heavy stews, curries.

- Pros: Excellent liquid containment; often compatible with tight-sealing PP lids.

Lid Options

The box is only half the solution. The lid mechanism defines the leak resistance.

- Paper/Foil Laminated Lids: These often fold into the box or sit on top. Good for heat retention but may not be 100% leak-proof for soups.

- PET/PP Plastic Lids: Clear lids allow customers to see the food. They usually snap onto a rolled rim. Essential for retail display.

- Heat-Sealed Film: For industrial catering or frozen meals, a film can be heat-sealed directly to the flange of the box.

4. Customization and Printing Capabilities

Branding is a primary reason buyers switch from generic aluminum trays to printed aluminum foil boxes. However, printing on foil requires specific techniques.

Printing Techniques

- UV Offset Printing: Ideal for high-quality, detailed graphics. UV inks cure instantly and adhere well to non-porous foil surfaces.

- Flexography: Cost-effective for simple designs and high-volume runs (e.g., 50,000+ units).

- Embossing: Stamping logos or patterns directly into the foil/board creates a premium tactile feel without ink. This is popular for luxury brands.

Design Considerations for Foil

When designing for an aluminum substrate, remember that the background is metallic silver (or gold if tinted).

- White Ink: If you want accurate colors (like a bright red logo), the printer must lay down a base layer of white ink first. Otherwise, the colors will appear metallic and darker.

- Knockouts: utilizing the substrate’s natural silver color as part of the design can create striking effects.

5. Size and Capacity Guide

Selecting the right size minimizes food waste and controls portion costs. Capacities are typically measured in milliliters (ml) or ounces (oz).

| Size Category | Typical Capacity | Common Dimensions (LxWxH approx) | Ideal For |

|---|---|---|---|

| Small / Side | 400ml – 600ml | 140 x 100 x 40 mm | Rice sides, appetizers, desserts |

| Medium / Meal | 700ml – 1000ml | 170 x 120 x 50 mm | Standard entrees, pasta, salads |

| Large / Sharing | 1200ml – 2000ml | 220 x 160 x 60 mm | Family packs, whole roasted chicken, catering trays |

Note: Dimensions vary by manufacturer. Always request a die-line template before finalizing artwork.

6. Quality Assurance and Manufacturing Standards

When sourcing from a food packaging box manufacturer, quality assurance is paramount. Defects in foil boxes can lead to leaks, collapsed containers, and customer complaints.

Key Quality Tests

- Leakage Testing: Manufacturers should randomly sample boxes, fill them with a dyed liquid, and let them stand for a set period to check for seepage at the corners or bottom seams.

- Load Bearing Test: Boxes are stacked to simulate delivery conditions. The bottom box must not deform under the weight of 3-5 filled units.

- Adhesion Test: The foil laminate must not peel away from the paperboard, especially when exposed to steam or heat. Delamination is a critical failure.

- Microwave Safety Check: While solid metal trays cause arcing, some modern foil-laminated board structures are designed to be microwave-safe under specific conditions. Verify this capability explicitly if required.

7. Grease Resistance and Coatings

One of the primary functions of the aluminum foil box is grease resistance. Standard paper boxes rely on PE coatings, which can sometimes fail with extremely hot oils (like chili oil or fried chicken grease). Aluminum foil provides a superior physical barrier.

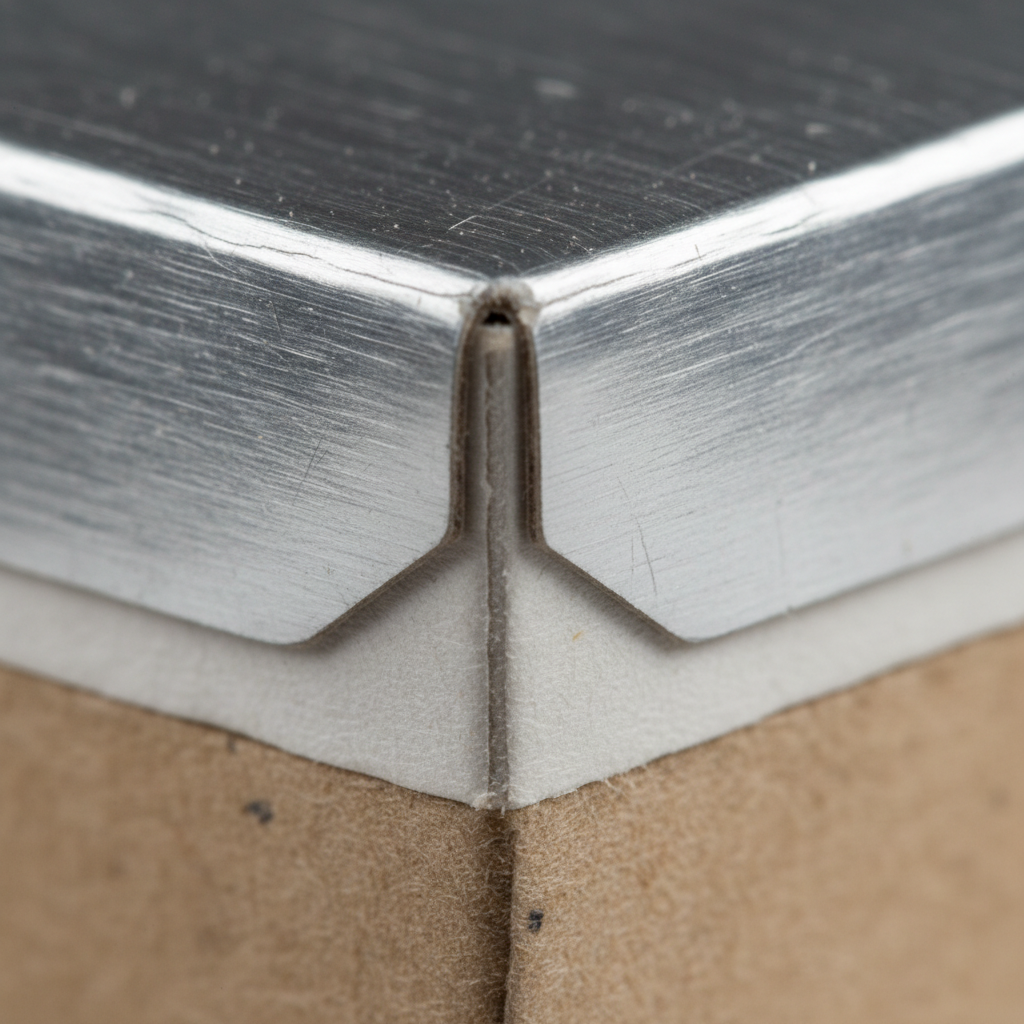

However, the internal seams are potential weak points. High-quality manufacturing involves precise folding and gluing (or heat sealing) of the corners to ensure the foil barrier is continuous. For extremely oily foods, ask your supplier about “web-corner” or “leak-proof corner” designs, where the material is folded rather than cut and glued, creating a seamless basin.

8. Sustainability and Recycling

Sustainability is a growing concern for international buyers. Aluminum is infinitely recyclable, but composite materials (paper + foil + plastic) can be challenging to process in standard recycling streams.

- Separability: Some advanced boxes are designed so the foil liner can be peeled away from the paperboard by the consumer, allowing both to be recycled separately.

- Recycled Content: Ask if the paperboard core uses recycled fibers (often legally restricted to non-contact layers) or if it is FSC-certified virgin pulp.

9. Buying Guide: How to Source Effectively

Navigating the procurement process requires attention to detail. Here is a checklist for engaging with suppliers.

Minimum Order Quantities (MOQ)

Custom printed aluminum foil boxes typically have higher MOQs than plain generic ones due to the setup costs of offset printing and die-cutting.

- Generic/Stock: Low MOQ (e.g., 1,000 units).

- Custom Logo (Flexo): Medium MOQ (e.g., 10,000 – 30,000 units).

- Full Custom Size/Shape: High MOQ (e.g., 50,000+ units) due to tooling costs.

Lead Times

Production timelines for custom orders generally range from 3 to 5 weeks after artwork approval. Shipping times must be added to this. Always factor in an extra week for the initial sampling and proofing phase.

Artwork and File Preparation

Suppliers will need vector files (AI, PDF, EPS) for printing. Ensure all fonts are outlined and pantone colors (PMS) are specified if strict color matching is required. Request a digital 3D mockup if possible before mass production.

Sampling Strategy

Never place a large bulk order without testing a physical sample. Use the sample to:

- Test actual portion sizes with your kitchen team.

- Verify the lid fit (is it too loose? too tight?).

- Check heat retention times.

For details on initiating this process, review the ordering process outlined by your supplier.

10. Common Pitfalls to Avoid

- Ignoring Lids: Buying boxes from one supplier and lids from another often results in a poor fit. Always buy matched sets.

- Overlooking Storage Space: Rigid boxes take up more warehouse space than flat-fold cartons. Ensure you have the logistics capacity to store thousands of erected boxes, or choose nesting designs that stack tightly.

- Assuming Microwave Safety: Never assume a foil box is microwave safe. Unless explicitly marked and tested, metal in a microwave is a fire hazard.

11. Use Cases and Industry Applications

Airline Catering

Airlines require lightweight, compact, and heat-resistant packaging. Foil boxes are standard for hot meal service as they fit perfectly into galley ovens and withstand re-heating cycles.

Bakery and Confectionery

Aluminum foil boxes are excellent for baking directly in the container. Brownies, tarts, and lasagnas can be baked, sold, and reheated in the same unit, reducing labor and cleaning costs.

Ghost Kitchens and Delivery

For businesses operating solely on delivery, packaging is the only physical touchpoint with the customer. A branded, high-quality gold or silver foil box elevates the perceived value of the meal, justifying higher price points.

12. Frequently Asked Questions (FAQ)

Q1: Can aluminum foil boxes be used in the microwave?

Generally, traditional aluminum containers cannot be used in microwaves due to arcing. However, some specially designed foil-laminated board containers with rounded corners and specific coating structures are microwave-safe. Always check the manufacturer’s specification sheet.

Q2: Are these boxes suitable for freezing?

Yes. Aluminum foil and PE-coated board are excellent for freezer storage. They resist cracking at low temperatures and prevent freezer burn better than standard paperboard.

Q3: What is the difference between a foil container and a foil-laminated box?

A foil container is made entirely of stamped aluminum (wrinkle-wall or smooth-wall). A foil-laminated box is made of paperboard with a thin foil layer glued to it. The laminated box offers better printability and a more premium “box-like” feel, whereas the all-foil container is more industrial.

Q4: Can I print full-color photos on a foil box?

Yes, using offset printing. However, a white base layer is usually required under the photo area to ensure the colors look natural and not metallic.

Q5: Is the aluminum layer on the inside or outside?

It can be either. Inside lamination is for grease/heat resistance. Outside lamination is for decorative metallic effects. Double-sided lamination is possible for premium applications.

Q6: How do I get a quote for custom sizes?

You will need to provide the desired dimensions (Length x Width x Height), the estimated quantity, and the artwork details. You can contact our team directly to discuss custom tooling options.

Q7: Do these boxes come with matching lids?

Most manufacturers offer compatible lids, either in plastic (PET/PP) or foil-laminated paper. These are usually sold separately or as a set.

Conclusion

Selecting the right aluminum foil box involves balancing aesthetic goals with functional requirements like heat retention and leak resistance. By understanding the material properties, printing constraints, and supply chain logistics, B2B buyers can secure packaging that not only protects their product but also enhances their brand.

Whether you are scaling a restaurant chain or sourcing for a distribution network, YBJ Packing offers a range of customizable solutions to meet these rigorous standards.

Ready to upgrade your food packaging? Request a quote or get a sample today to see the quality difference firsthand.