In the competitive world of Quick Service Restaurants (QSR), packaging is no longer just a vessel for food; it is a critical component of brand identity, operational efficiency, and sustainability strategy. A notable concept that has captured the attention of packaging engineers and procurement managers alike is the integrated "all-in-one" hamburger box design, popularized by designer Robert Bye. This structural innovation reimagines how a standard meal—burger, fries, and drink—can be carried without the need for an external tote bag.

For brands looking to optimize their packaging supply chain, analyzing such designs offers valuable insights into material reduction and consumer convenience. This article explores the mechanics of this innovative design, the technical considerations for manufacturing similar solutions, and how brands can leverage structural engineering to reduce waste.

Deconstructing the All-in-One Design Concept

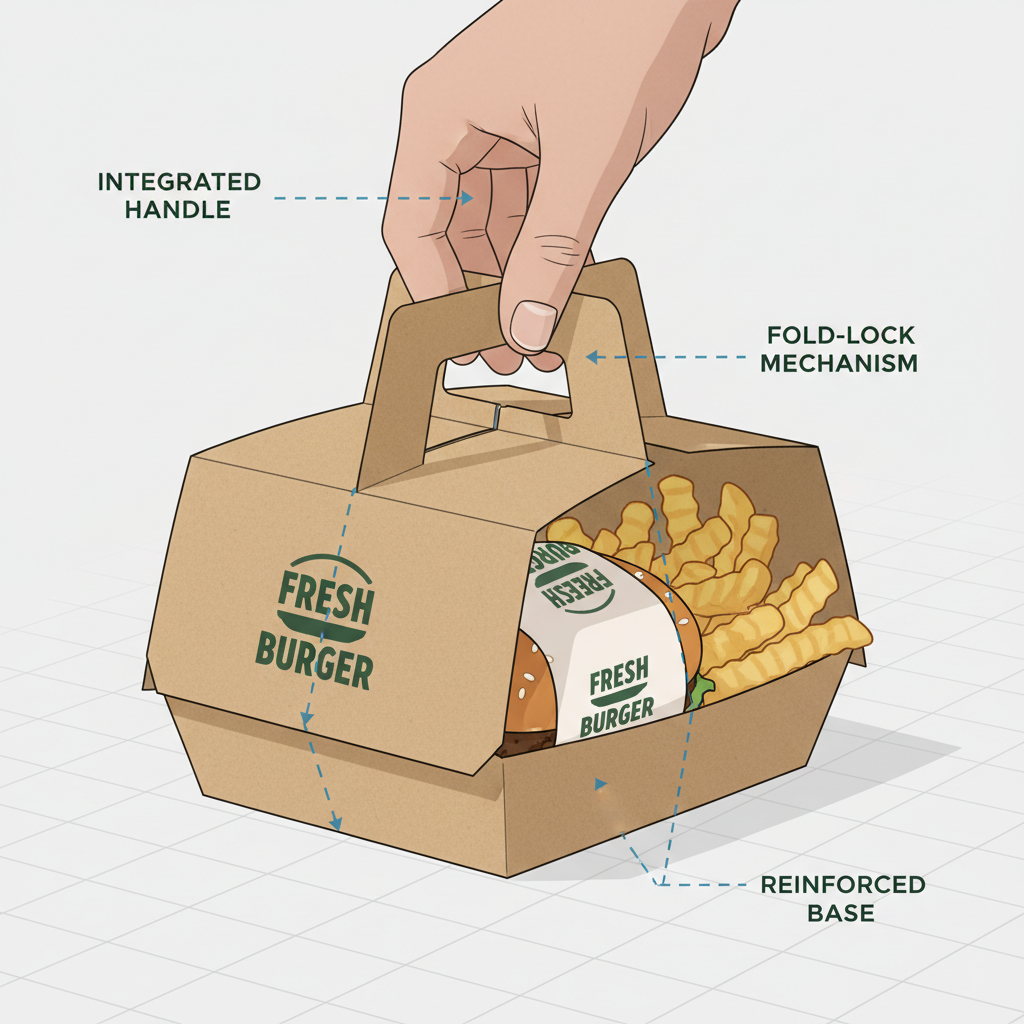

The core philosophy behind this packaging concept is consolidation. Traditionally, a fast-food meal consists of three distinct packaging units (burger box/wrap, fry scoop, drink cup) placed inside a fourth unit (a paper or plastic carry bag). The Robert Bye concept eliminates the fourth unit entirely by engineering the primary packaging to perform the carrying function.

Structural Mechanics

The design relies on a clever use of folding carton mechanics. When unfolded, the structure appears as a single elongated sheet of paperboard, die-cut into specific zones:

- The Base Compartment: A standard clamshell-style base intended for the hamburger.

- The Upper Compartment: A connected section designed to hold french fries vertically.

- The Integrated Lid/Handle: An elongated flap with a circular die-cut.

When assembled, the fries compartment folds down to act as the lid for the burger section. The elongated flap then folds over, and the circular hole secures the beverage cup. The weight of the drink effectively locks the package together, creating a balanced, single-handed carry unit.

Benefits of Integrated Packaging for QSR Chains

For procurement officers and brand owners, shifting to a consolidated design offers several strategic advantages.

1. Sustainability and Material Reduction

The most immediate benefit is the elimination of the outer carry bag. By reducing the Stock Keeping Unit (SKU) count, businesses can significantly lower their paper consumption. This aligns with global trends toward minimizing single-use packaging waste. For more on how the industry is evolving, read about the <a href="Innovation and Development of Hamburger and French Fries Packaging“>innovation and development of hamburger and french fries packaging.

2. Enhanced Consumer Experience

Functionality drives customer satisfaction. A package that allows a customer to carry a full meal and a drink in one hand is highly convenient, especially for on-the-go consumption. It also presents a unique "unboxing" experience that can differentiate a brand in a crowded market.

3. Supply Chain Efficiency

Reducing the number of packaging components simplifies inventory management. Instead of sourcing, storing, and tracking boxes, scoops, and bags separately, a brand might only need to manage the primary container and the drink cup.

Technical Manufacturing Considerations

While the concept is appealing, mass manufacturing such a complex structure requires careful attention to material specifications and production processes.

Material Selection

To support the weight of a full meal—including a heavy beverage—standard lightweight folding box board (FBB) may not suffice. Manufacturers typically recommend:

- Wet Strength Kraft Board: Essential for maintaining integrity if condensation from a cold drink comes into contact with the paper.

- Grammage: A higher GSM (grams per square meter) is likely required compared to a standard burger box to prevent the handle/lid from tearing under load.

- Grease Resistance: Since fries and burgers are in direct contact with the structure, a food-safe aqueous coating or a PE (polyethylene) lining is necessary to prevent grease spots from compromising the box’s aesthetics and strength.

Die-Cutting and Folding

Complex designs increase the complexity of the die-cutting process. The tooling must be precise to ensure that locking tabs engage smoothly without slowing down the packing speed at the restaurant. If the assembly is too difficult for restaurant staff, operational efficiency drops, negating the benefits of the design.

Is This Design Right for Your Brand?

Before commissioning a custom structural design similar to this concept, buyers should weigh the pros and cons.

| Feature | Standard Packaging | Integrated All-in-One Design |

|---|---|---|

| Material Cost | Lower per unit (but requires bag) | Higher per unit (but saves bag cost) |

| Storage Space | High (multiple SKUs) | Medium (larger flat footprint) |

| Assembly Speed | Fast (standard workflows) | Slower (requires folding training) |

| Brand Impact | Standard | High (Innovative/Eco-friendly) |

Buying Guide: Customizing Your Food Packaging

If you are interested in developing a unique structural packaging solution, here is what you need to prepare for the manufacturing process:

- CAD Samples: Always request a white unprinted sample (dummy) to test the structural integrity with actual food products before committing to a full run.

- Artwork & Branding: Complex folds offer unique branding real estate. Ensure your artwork accounts for which panels will be visible when the box is closed versus open.

- MOQ (Minimum Order Quantity): Custom structures often require new die-cut molds, which may necessitate higher MOQs (typically starting from 10,000 to 50,000 units depending on complexity) to amortize tooling costs.

Frequently Asked Questions

Can this design hold large beverages?

The structural strength depends on the cardboard grade used. For large drinks (e.g., 32oz), reinforced kraft board is recommended to prevent the handle from tearing.

Is this packaging recyclable?

Yes, provided the coatings used are eco-friendly. Water-based grease barriers are fully recyclable, whereas PE-lined boards may require specialized recycling facilities.

Can I customize the size for different menu items?

Absolutely. As a custom manufacturer, YBJ Packing can adjust the dimensions of the burger and fry compartments to fit specific menu items, from sliders to gourmet burgers.

How does this impact storage space in the restaurant?

These boxes ship flat, which is space-efficient. However, because the unfolded footprint is larger than a standard burger box, they may require slightly more shelf depth than traditional clamshells.

Request a Quote for Custom Food Packaging

Innovative packaging can set your brand apart while reducing environmental impact. Whether you need a standard solution or a completely new structural design, our team is ready to assist with engineering, prototyping, and mass production.

Contact us today to request a quote or get a sample of our latest packaging solutions.