Introduction

In the competitive landscape of food service and retail, packaging serves two distinct purposes: protection and presentation. For bakeries, delis, and food brands, the window paper bag has emerged as a critical tool that bridges the gap between these two needs. It offers the structural integrity and eco-friendly appeal of paper while providing the product visibility necessary to drive impulse purchases.

Buyers in the B2B sector—ranging from procurement managers at large grocery chains to owners of artisanal bakeries—must navigate a complex array of specifications when sourcing these bags. The difference between a successful product launch and a packaging failure often lies in technical details: grease resistance levels, film clarity, seam strength, and barrier properties.

This comprehensive guide explores the technical and commercial aspects of sourcing window paper bags. We will cover material science, sizing standards, customization options, and the logistical considerations of ordering custom window paper bags in bulk.

The Strategic Value of Visibility in Food Packaging

Why choose a window bag over a solid kraft bag? The answer lies in consumer psychology and merchandising strategy. In a grab-and-go environment, customers rely heavily on visual cues to assess freshness and quality.

Merchandising and Impulse Buys

A clear window transforms standard packaging into a display case. For items like artisan breads, cookies, or colorful confectionery, the product itself is the best marketing asset. Hiding it behind opaque paper requires the customer to trust the label entirely. A window bag allows the crust of the bread, the texture of the cookie, or the freshness of the salad to trigger the appetite directly.

Trust and Transparency

Visual access builds trust. When a customer can see the quantity and condition of the food inside, they are less likely to hesitate. This is particularly important for premium organic products or high-ticket bakery items where the consumer wants to verify quality before purchasing.

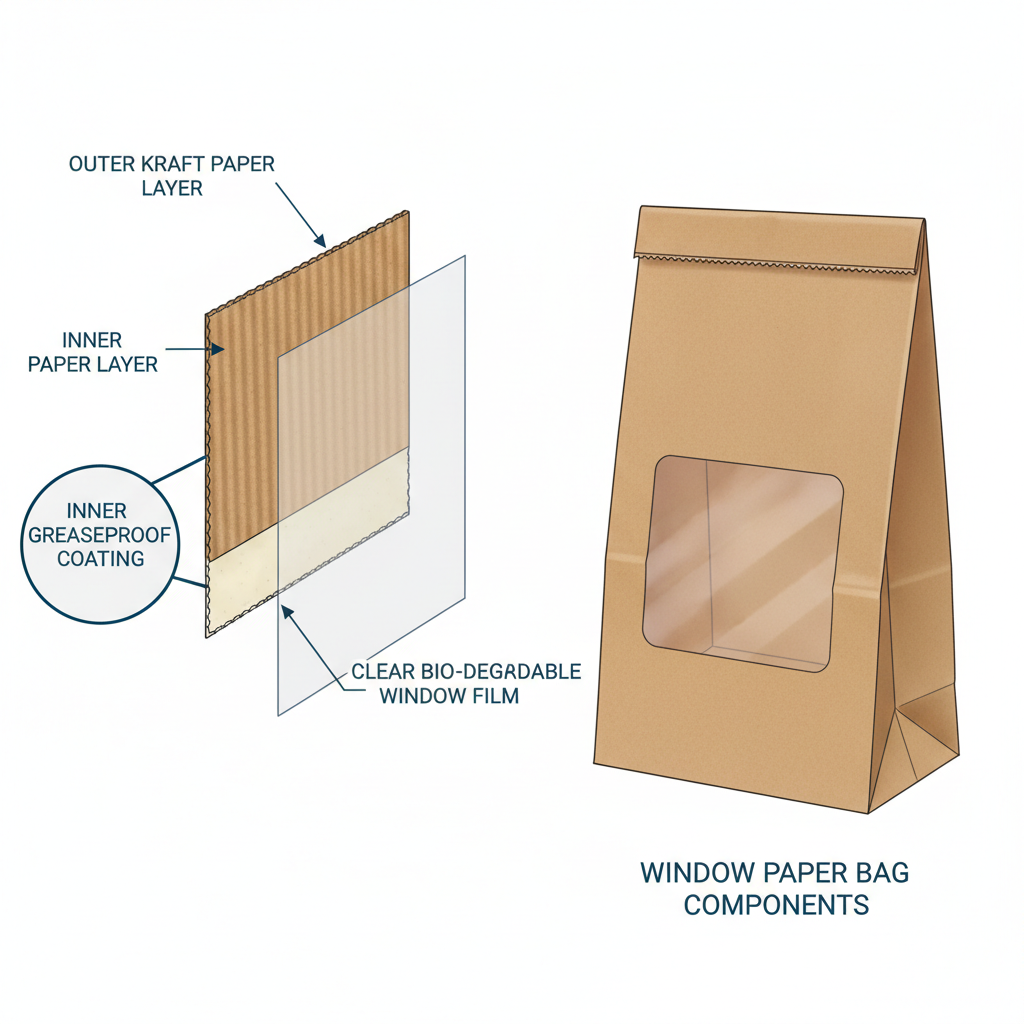

Anatomy of a High-Quality Window Paper Bag

A window paper bag is a composite product, typically combining a paper substrate with a plastic (or bioplastic) film. Understanding the interplay between these materials is essential for selecting the right packaging for your specific application.

1. Paper Base Materials

The structural body of the bag is usually made from Kraft paper, chosen for its tensile strength and elasticity. The choice of paper impacts both the aesthetic and the durability of the bag.

- Natural Kraft (Brown): Unbleached paper that offers a rustic, organic, and eco-friendly look. It is highly popular in the organic food sector. It effectively hides grease stains if the paper is treated properly, though dark oil spots can still show on untreated versions.

- Bleached Kraft (White): Chemically treated to remove the natural brown color. This provides a clean, sterile appearance and serves as an excellent canvas for vibrant, full-color printing. It is often preferred by pharmaceutical or high-end confectionery brands.

- Recycled Kraft: Made from post-consumer waste. While sustainable, the fibers are shorter, meaning the tensile strength may be slightly lower than virgin Kraft. It is suitable for lighter items but may require higher GSM (grams per square meter) for heavy loads.

- GSM Ranges: Common weights range from 40 GSM to 80 GSM for standard bakery bags. Heavier items like coffee beans or granola may require 100+ GSM paper stocks.

2. Window Film Options

The window material determines the clarity, heat resistance, and breathability of the package.

- BOPP (Biaxially Oriented Polypropylene): Offers excellent clarity and moisture resistance. It is a standard choice for ambient temperature products.

- PET (Polyethylene Terephthalate): Stronger and more heat-resistant than BOPP. It is often used when the bag might be subjected to higher temperatures or requires a stiffer window.

- CPP (Cast Polypropylene): Known for high tear resistance and heat sealability.

- PLA (Polylactic Acid): A biodegradable and compostable option derived from corn starch. This is the preferred choice for brands focusing on a 100% plastic-free or compostable narrative. However, PLA has lower heat resistance and is not suitable for hot foods straight out of the oven.

3. Adhesives and Construction

The method of attaching the window to the paper is a critical quality control point. Low-quality manufacturing can lead to “tunneling” (where the film bubbles away from the paper) or delamination. High-quality food packaging bags use food-grade adhesives applied with precision to ensure a flat, secure bond that prevents crumbs or liquids from leaking between the layers.

Grease Resistance and Barrier Coatings

One of the most common failures in food packaging is grease leakage. A standard paper bag will absorb oil from doughnuts, croissants, or sandwiches, leading to unsightly spotting and potentially compromising the bag’s strength.

PE Lining vs. Greaseproof Paper

- PE (Polyethylene) Lining: A thin layer of plastic is extruded onto the inner surface of the paper. This provides a total barrier against grease and moisture. It allows the bag to be heat-sealed but makes recycling more difficult as the paper and plastic must be separated.

- Greaseproof Paper (Kit Levels): The paper is treated chemically (often with fluorocarbons or bio-based alternatives) to resist oil penetration without a plastic film. This maintains the paper’s breathability, which is crucial for crusty breads that need to release steam to stay crisp.

Understanding Kit Levels

Grease resistance is measured in “Kit levels” ranging from 1 to 12.

- Kit 1-3: Low resistance. Suitable for dry goods like flour or sugar.

- Kit 4-6: Medium resistance. Good for cookies, pretzels, or bread with low butter content.

- Kit 7-9: High resistance. Required for pastries, croissants, and oily sandwiches.

- Kit 10-12: Maximum resistance. Used for fried foods or items with heavy oil saturation.

Buyers must specify the nature of the food product to the manufacturer to ensure the correct grease resistance level is applied.

Sizing and Capacity: Finding the Right Fit

Standardizing bag sizes helps optimize inventory and shelf space. However, the dimensions must accommodate the product without crushing it or leaving excessive empty space.

Understanding Gussets

The capacity of a bag is largely determined by its gussets (folds).

- Side Gussets: Expand the width of the bag. Ideal for flat items stacked vertically or bulky items like loaves of bread.

- Bottom Gussets (Block Bottom): Create a flat base that allows the bag to stand upright on a shelf. This is essential for display purposes and makes filling the bag easier for staff.

Common Dimensions (Width x Gusset x Height)

While custom sizes are available, industry standards often include:

- Baguette Bags: Long and narrow (e.g., 10cm x 4cm x 60cm). Usually feature a central strip window.

- Cookie/Donut Bags: Square or rectangular (e.g., 12cm x 6cm x 22cm). Often have a large front window.

- Toast/Loaf Bags: Wider block bottom bags (e.g., 20cm x 10cm x 30cm) designed to hold a full sliced loaf.

Customization and Branding Opportunities

For B2B buyers, the window bag is a mobile billboard. Effective branding can increase brand recall and perceived value.

Printing Techniques

- Flexographic Printing: The industry standard for paper bags. It uses flexible relief plates and fast-drying inks. It is cost-effective for high volumes (10,000+ units) and supports up to 6-8 colors.

- Offset Printing: Offers higher image resolution and smoother gradients but is typically more expensive and used for premium, lower-volume runs or rigid box packaging rather than flexible bags.

Die-Cut Window Shapes

The window doesn’t have to be a simple rectangle. Manufacturers can create custom die-cut shapes to align with branding.

- Strip Windows: Running vertically down the center (common for bread).

- Panoramic Windows: Extending across the side gussets for visibility from multiple angles.

- Custom Shapes: Windows shaped like a leaf, a heart, or a logo outline can differentiate a brand on the shelf.

Closures and Accessories

- Tin Ties: Metal strips encased in paper at the top of the bag. They allow the bag to be reclosed, preserving freshness. Ideal for coffee, loose-leaf tea, or cookies consumed over time.

- Peel and Seal: An adhesive strip for easy, tamper-evident sealing. Great for takeaway delivery orders.

- Heat Sealable: Requires a PE or PLA lining. Provides an airtight seal for long shelf life.

Use Cases and Industry Applications

Different food sectors have unique requirements for window paper bags.

1. Artisan Bakeries

Requirement: Breathability and Visibility.

Solution: Uncoated Kraft paper with a perforated BOPP window or a micro-perforated strip. This allows steam to escape from warm bread, preventing the crust from becoming soggy, while still showing the product.

2. Grab-and-Go Delis

Requirement: Grease Resistance and Stability.

Solution: Block bottom bags with Kit 7+ grease resistance or light PE lining. The flat bottom ensures the sandwich stays upright in the display fridge.

3. Confectionery and Dry Goods

Requirement: Barrier Protection and Aesthetics.

Solution: White Kraft bags with high-clarity windows and tin-tie closures. The closure allows the customer to re-seal the bag after taking a few treats.

4. Hot Food Takeaway

Requirement: Heat Retention and Grease Control.

Solution: Foil-lined paper bags (sometimes with small windows) or heavy-duty poly-lined bags. Note: Large plastic windows can melt or warp with very hot fried foods, so careful material selection is needed.

Sustainability and Compliance

As regulations regarding single-use plastics tighten globally, B2B buyers must consider the environmental footprint of their packaging.

The Mixed Material Challenge

Standard window bags combine paper and plastic, which can complicate recycling. In many jurisdictions, the consumer must separate the film from the paper before recycling.

Sustainable Solutions

- PLA Windows: Using corn-starch-based films allows the entire bag to be industrially compostable (depending on the paper inks and adhesives used).

- Perforated Paper Windows: Instead of a plastic film, some designs use a mesh of paper or simple die-cut holes (if hygiene regulations allow) to provide visibility without plastic.

- Removable Windows: Bags designed with a perforated tear-line that makes it easy for the consumer to separate the plastic window from the paper body for proper recycling.

Manufacturing and Quality Assurance

When evaluating a supplier, understanding the manufacturing process helps in assessing their capability.

Production Workflow

- Printing: The paper roll is printed with the brand design.

- Die Cutting: The window shape is cut out of the paper.

- Lamination/Patching: The film is glued over the cut-out area.

- Forming: The paper is folded into a tube, gussets are formed, and the bottom is glued.

- Cutting/Counting: The continuous tube is cut into individual bags and bundled.

Quality Checks

Reliable manufacturers perform specific tests:

- Seam Strength Test: Ensuring the bottom and back seams do not burst under load.

- Window Adhesion Test: Verifying the film does not peel off.

- Migration Testing: Ensuring inks and adhesives do not leach into the food (crucial for food safety compliance).

Procurement Guide: Ordering Wholesale

Ready to place an order? Here is a checklist for B2B buyers to ensure a smooth procurement process.

1. Minimum Order Quantities (MOQ)

Custom printed window bags typically require higher MOQs than plain stock. This is due to the setup time for printing plates and die-cutters. Typical MOQs might range from 10,000 to 30,000 units depending on the complexity. Stock sizes may be available in smaller quantities (e.g., 1,000 units).

2. Lead Times

- Sampling: 7-10 days for a physical proof.

- Production: 20-30 days after artwork approval.

- Shipping: Depends on the destination (Air freight vs. Sea freight).

3. Artwork Preparation

To avoid delays, provide artwork in vector formats (AI, PDF, EPS). Specify Pantone (PMS) colors to ensure brand consistency. Always request a digital dieline template from the manufacturer before designing.

4. Storage Considerations

Paper bags are hygroscopic (they absorb moisture). Store bulk inventory in a cool, dry place, off the ground on pallets, to prevent warping or mold growth.

For detailed steps on initiating an order, you can visit our how to order page.

Frequently Asked Questions (FAQ)

1. Can window paper bags be used for hot foods?

Yes, but the window material matters. Standard BOPP may warp at high temperatures. For hot rotisserie chickens or hot breads, specialized heat-resistant films or perforated films (to release steam) are recommended.

2. Are custom window shapes more expensive?

There is usually a one-time tooling cost for creating a custom die-cutting mold. However, the per-unit cost difference is often negligible for large production runs.

3. What is the difference between “food grade” and standard paper?

Food grade paper is manufactured without harmful bleaching agents or recycled content containing contaminants. It complies with FDA or EU regulations for direct food contact. Always insist on certified food-grade materials.

4. Can I get a window bag that is 100% biodegradable?

Yes. By combining unbleached Kraft paper with a PLA (polylactic acid) window and using soy-based inks, the entire bag can be biodegradable and compostable.

5. Do window bags affect the shelf life of the product?

They can. Light exposure can degrade certain high-fat products (like nuts) faster than opaque packaging. However, for bakery items consumed within 24-48 hours, the impact is minimal. Barrier coatings can be added to extend shelf life.

6. How do I determine the correct bag size?

Measure your product’s Height, Width, and Depth. Add 1-2 cm of clearance to the Width and Depth for easy filling. For the Height, add enough space for the closure method (e.g., folding over or heat sealing).

7. Can you print on the window film itself?

Yes, it is possible to print logos or patterns directly on the plastic window, though it is more common and cost-effective to print on the paper surrounding the window.

Conclusion

Window paper bags offer a versatile, attractive, and functional packaging solution for the food service industry. They balance the mechanical protection of paper with the marketing power of transparency. By carefully selecting the right combination of paper weight, grease resistance, window material, and closure type, buyers can enhance their product presentation while ensuring freshness and safety.

Whether you are launching a new line of artisan cookies or sourcing packaging for a nationwide bakery chain, understanding these technical details ensures you get the best value and performance from your packaging supplier.

Ready to enhance your product presentation?

At YBJ Packing, we specialize in high-quality, custom food packaging solutions tailored to your brand’s needs. Contact us today to request a quote or get a sample of our premium window paper bags.