Introduction

In the competitive food service industry, packaging serves two critical functions: preserving product integrity and communicating brand value. For commercial bakeries, patisseries, and food distributors, choosing the right bakery bag is not merely an aesthetic decision—it is an operational necessity. The wrong material can lead to grease spots, premature staling, or structural failure during transport, all of which damage the customer experience.

This comprehensive guide is designed for procurement officers, operations managers, and brand owners sourcing wholesale bakery bags. We will examine the technical specifications of paper materials, the science of grease resistance, sizing standards, and the nuances of custom manufacturing. By understanding these variables, buyers can optimize their supply chain for both cost-efficiency and product quality.

The Role of Packaging in Bakery Operations

Bakery products are sensitive to environmental factors. Moisture control is a delicate balance; too much airflow dries out bread, while too little traps condensation, making crusts soggy. The packaging must act as a precise barrier. Furthermore, in a B2B context, packaging efficiency impacts the bottom line. Bags that are difficult to open or fill slow down service lines, increasing labor costs during peak hours. Therefore, the ideal bakery bag combines appropriate barrier properties with ergonomic design for rapid fulfillment.

Analyzing Bakery Bag Materials: A Deep Dive

The foundation of any high-performance bakery bag is the raw material. Manufacturers typically offer a spectrum of paper grades, each suited to specific applications. Understanding the difference between these substrates is the first step in strategic sourcing.

Brown Kraft Paper (Natural & Strong)

Unbleached brown Kraft paper is the industry standard for robust, eco-conscious packaging. Produced from wood pulp with minimal chemical processing, it retains strong fibers that provide excellent tensile strength. This makes it ideal for heavy items like artisan sourdough loaves or bulk orders of bagels.

From a branding perspective, brown Kraft communicates an organic, rustic, and homemade aesthetic. It is naturally breathable, allowing hot steam to escape, which is crucial for maintaining the crisp crust of fresh-baked goods. Typical weights range from 30 GSM (grams per square meter) for light cookies to 80+ GSM for heavy-duty bread sacks.

Bleached White Kraft (Clean & Printable)

Bleached Kraft paper undergoes a treatment to remove the natural brown lignin, resulting in a pristine white surface. While structurally similar to brown Kraft, the white surface offers a superior canvas for branding. Colors appear more vibrant, and complex logos print with higher contrast.

White Kraft is often preferred by modern bakeries and patisseries aiming for a sleek, minimalist, or hygienic look. It is widely used for custom food packaging where precise color matching (Pantone) is required.

Greaseproof and Glassine Papers

Standard Kraft paper is porous and will absorb oils. For products with high butter or oil content—such as croissants, muffins, or donuts—greaseproof paper is essential. This material is beaten during the pulping process to break down fibers, creating a dense, non-porous sheet.

Glassine is a step further; it is super-calendered (pressed between rollers) to create a smooth, glossy, and semi-transparent finish. It offers excellent grease resistance without chemical coatings, making it a preferred choice for lining bags or for direct contact with sticky confectioneries.

Laminated Options (Poly-lined)

For maximum barrier protection, paper can be laminated with a thin layer of polyethylene (PE) or polypropylene (PP). This plastic lining provides a complete moisture and grease barrier. These bags are often heat-sealable, allowing for extended shelf life.

However, buyers must weigh the performance benefits against sustainability goals. While lined bags are superior for preventing leaks in very oily products, they can be more challenging to recycle than mono-material paper options. Biodegradable coatings (like PLA) are emerging as alternatives, offering similar barriers with improved compostability profiles.

Understanding Grease Resistance and Barrier Properties

One of the most common complaints in bakery packaging is “spotting”—when oil seeps through the bag, staining the customer’s hands or clothes. To prevent this, manufacturers use specific treatments. It is vital to specify the level of grease resistance required in your RFQ (Request for Quote).

The Kit Level System Explained

The oil resistance of paper is often measured using the “Kit Test,” which rates resistance on a scale from 1 to 12.

- Kit 1-3: Low resistance. Suitable for dry goods like baguettes or crackers.

- Kit 4-6: Medium resistance. Ideal for cookies, muffins, and standard pastries.

- Kit 7-9: High resistance. Necessary for fried items, buttery croissants, or donuts.

- Kit 10+: Extreme resistance. Used for industrial applications or very oily foods.

Specifying the correct Kit level ensures you do not overpay for unnecessary processing while avoiding product failure.

Coated vs. Uncoated: Making the Right Choice

Uncoated papers rely on the density of the fiber (like glassine) for protection. Coated papers use a chemical or mineral application (often clay or safe polymers) to seal the surface. Coated papers generally offer better printability for high-resolution graphics but may have a different tactile feel. For brands prioritizing a “natural” touch, an uncoated, high-Kit greaseproof paper is often the best compromise.

Sizing and Structural Styles

Selecting the correct bag architecture impacts storage efficiency and product presentation. Bakery bags generally fall into three main structural categories.

Flat and Satchel Bags (V-Bottom)

These are the most economical options.

- Flat Bags: Have no gussets. They are two-dimensional and best for thin items like large cookies or pretzels.

- Satchel Bags: Feature side gussets (expandable sides) but a sharp V-shaped bottom.

Satchel bags are the industry standard for baguettes and French sticks. They are easy to store flat and pop open quickly. However, they do not stand up on their own, making them less suitable for display shelves.

Square Bottom (SOS) Bags

SOS stands for “Self-Opening Sack.” These bags feature side gussets and a rectangular block bottom, similar to a classic grocery bag.

- Pros: They stand upright on counters, making filling easier and improving display visibility. They can hold bulkier items like loaves, bundles of pastries, or takeaway orders.

- Cons: Slightly higher manufacturing cost due to the complex bottom construction.

For premium branding, SOS bags are often the preferred choice as they act as a mini-billboard on the customer’s table.

Window Bags for Product Visibility

Visual appeal drives sales. Window bags incorporate a clear panel (made from BOPP, PET, or PLA) into the paper structure. This allows customers to see the freshness of the product without opening the package.

Key Consideration: Ensure the window material is compatible with the product temperature. Hot breads placed in a standard plastic window bag can cause fogging. Anti-fog films or perforated windows are available for hot applications to release steam while maintaining visibility.

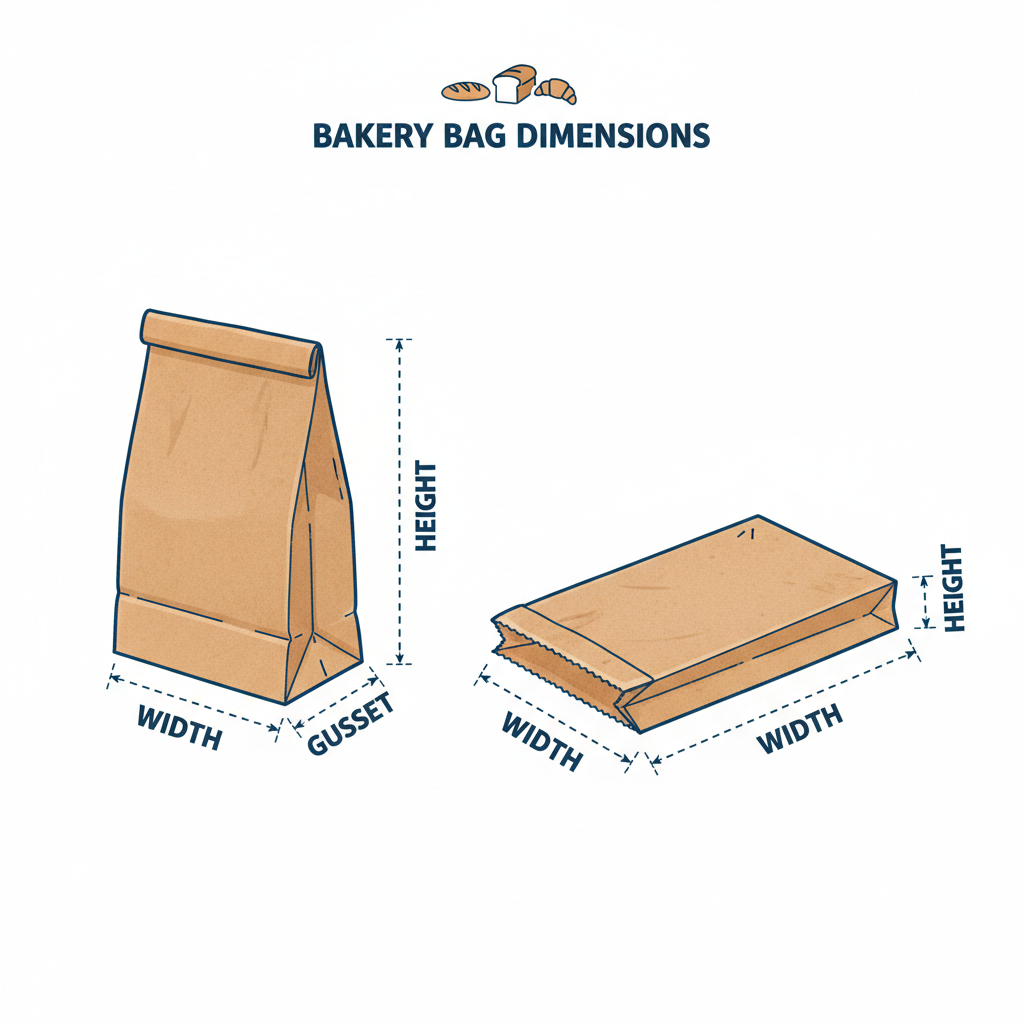

How to Measure a Bakery Bag Correctly

To avoid errors when ordering custom bakery bags, use the standard industry dimension format: Width (W) x Gusset (G) x Height (H).

- Width: The face of the bag.

- Gusset: The depth of the side expansion (sometimes listed as Side Gusset or Bottom Gusset depending on style).

- Height: The vertical length from top to bottom.

Always clarify if the dimensions are internal (usable space) or external, although external is the manufacturing standard.

Customization and Branding Capabilities

Packaging is a mobile advertisement. Custom printing transforms a commodity item into a brand asset.

Printing Technologies

Flexographic Printing (Flexo): The most common method for wholesale food packaging. It uses flexible relief plates and fast-drying, water-based inks (food safe). It is cost-effective for medium to large runs (10,000+ units) and handles simple logos and text patterns well.

Offset Printing: Used for high-end, photo-quality images. It is more expensive and typically requires higher minimums but delivers superior detail and color depth.

Design Considerations for Food Packaging

- Ink Safety: Always verify that the manufacturer uses food-grade, low-migration inks, especially if the design extends to the interior or rim of the bag.

- Coverage: Heavy ink coverage can sometimes affect the paper’s breathability or smell. For bakery items, minimalist designs often work best to preserve the natural aroma of the food.

- Artwork Files: Manufacturers typically require vector files (AI, PDF, EPS) to ensure crisp lines during plate creation.

Use Case Scenarios: Matching Bag to Product

Different baked goods impose different physical demands on packaging. Here is a quick guide to matching your product to the right bag.

Hot Breads and Baguettes

Requirement: Breathability.

Solution: Micro-perforated plastic or standard Kraft paper. Avoid fully sealed poly-lined bags, as the trapped steam will soften the crust (the “soggy baguette” effect). A long satchel bag with a strip window (perforated) is the gold standard.

Pastries and Croissants (High Grease)

Requirement: Grease resistance and structural protection.

Solution: SOS (block bottom) bag made from Kit 7+ greaseproof paper. The block bottom prevents the delicate pastry from being crushed, while the greaseproof layer prevents butter stains.

Cookies and Confectionery

Requirement: Air barrier (to keep crispness) and grease resistance.

Solution: Laminated bags or tin-tie bags. Tin-tie bags (bags with a reclosable metal strip at the top) are excellent for cookies as they allow the customer to reseal the pack, maintaining freshness over time.

Quality Assurance and Manufacturing Standards

When vetting a bakery bag supplier, inquire about their quality control processes. Key metrics include:

- Dimensional Tolerance: Acceptable variance in size (usually +/- 2-5mm).

- Seam Strength: The adhesive used on the bottom and back seams must withstand the weight of the product without bursting.

- Load Testing: Verifying the bag can hold the target weight (e.g., 1kg or 2kg) without tearing.

- Food Safety Compliance: Ensure the facility follows GMP (Good Manufacturing Practices) and materials comply with relevant food contact regulations (like FDA or EU standards).

Procurement Guide: Ordering Wholesale Bakery Bags

Navigating the ordering process efficiently requires preparation. Here is what you need to know before you contact our team.

Minimum Order Quantities (MOQ)

Custom manufacturing involves setup costs (machine calibration, printing plates). Therefore, MOQs are standard.

- Plain / Stock Bags: Usually have lower MOQs (e.g., 1,000 – 5,000 units).

- Custom Printed Bags: MOQs typically start at 10,000 to 30,000 units depending on the size and complexity. Higher volumes significantly reduce the unit cost.

Lead Times and Logistics

Production times vary based on complexity.

- Digital Proofing: 2-4 days.

- Production: Typically 15-25 days after artwork approval.

- Shipping: Depends on the destination and mode (sea vs. air). For international bulk orders, sea freight is the most economical but requires planning 4-6 weeks in advance.

For detailed information on the process, review our how to order guide.

Frequently Asked Questions (FAQ)

1. Can I get bakery bags that are both greaseproof and recyclable?

Yes. Uncoated greaseproof papers (processed mechanically to be dense) are fully recyclable and compostable. Bags with clay coatings are also often recyclable. However, bags laminated with plastic (PE) usually require specialized recycling facilities. Always check local regulations.

2. What is the difference between GSM and Microns?

GSM (Grams per Square Meter) measures weight, while Microns measure thickness. In paper packaging, GSM is the standard metric. A higher GSM generally implies a thicker, stiffer bag, but material density also plays a role.

3. Do you offer custom sizes or only standard sizes?

While standard sizes (e.g., 4lb, 6lb, 12lb bags) are cost-effective due to existing molds, custom dimensions are entirely possible. Custom sizing allows for a perfect product fit, reducing material waste and movement inside the bag.

4. How should I store paper bakery bags?

Paper is hygroscopic (absorbs moisture). Store bags in a cool, dry place, off the ground, and away from direct sunlight. High humidity can cause bags to curl or stick, while extreme dryness can make them brittle.

5. What is the best bag for hot roasted chicken vs. bread?

Hot chicken requires a leak-proof, often foil-lined or heavy poly-lined bag to contain juices and heat. Bread requires a breathable paper bag to prevent sogginess. Using a chicken bag for bread would ruin the crust.

6. Can I print on the inside of the bag?

Printing on the direct food contact surface is generally discouraged unless using specific, highly regulated techniques. It is safer and more common to print on the exterior. If an interior color is desired, using colored paper stock is a safer alternative.

Conclusion

Choosing the right bakery bag is a convergence of food science, logistics, and branding. From the breathability of the paper to the grease resistance of the coating, every specification plays a role in how your product is received by the end consumer. By defining your requirements regarding size, material, and print early in the procurement process, you ensure a smoother production run and a better final product.

At YBJ Packing, we specialize in helping businesses navigate these technical choices to find the perfect packaging solution. Whether you need high-volume plain bags or bespoke branded packaging, our team is ready to assist.

Ready to upgrade your food packaging? Request a quote today or ask for a sample kit to test our materials firsthand.