Introduction: The Strategic Value of Aluminum Foil Packaging in Food Service

In the high-volume world of food service and industrial catering, packaging is rarely just about containment. It is a critical component of operational efficiency, food safety, and brand presentation. For procurement managers, restaurant chains, and food distributors, sourcing custom aluminum foil food containers offers a unique balance of thermal performance, structural integrity, and cost-effectiveness.

Unlike plastic or paper alternatives, aluminum foil containers possess distinct barrier properties that make them indispensable for specific applications—ranging from airline catering and “meals on wheels” programs to upscale bakery operations and takeaway service. However, navigating the wholesale market requires a technical understanding of specifications. Not all foil containers are created equal; variations in alloy composition, temper, rim style, and coating can significantly impact performance on the production line and in the consumer’s hands.

This comprehensive guide explores the technical and commercial landscape of purchasing aluminum foil food containers in bulk. We will dismantle the complexities of customization—including printing limitations and embossing options—and provide a detailed roadmap for selecting the right specifications for your food products. Whether you are launching a new ready-to-eat meal line or optimizing a restaurant chain’s supply chain, this guide ensures you make informed, profitable purchasing decisions.

1. Why Aluminum? The Material Science of Food Preservation

Before diving into customization, it is essential to understand why aluminum remains a dominant material in the food packaging sector. The material’s popularity is driven by its functional properties, which directly translate to shelf-life extension and operational flexibility.

Thermal Versatility

Aluminum foil containers are dual-ovenable, meaning they can withstand the high heat of conventional ovens and the specific conditions of microwave ovens (provided modern usage guidelines are followed). Conversely, they perform exceptionally well in blast freezers. This temperature range—from -40°C to over 250°C—allows a single container to travel from the production line to the freezer, to the logistics chain, and finally to the consumer’s oven without warping, cracking, or melting.

Absolute Barrier Protection

Unlike porous paper or permeable plastics, aluminum foil provides a total barrier against light, gases (oxygen), moisture, and bacteria. For wholesale buyers dealing with sensitive foods—such as dairy-based baked goods or aromatic curries—this barrier is crucial for preventing spoilage and maintaining flavor integrity over long supply chains.

Sustainability and Circular Economy

In an era where sustainability dictates procurement policies, aluminum stands out. It is infinitely recyclable without loss of quality. For B2B buyers, switching to aluminum packaging can be a significant selling point, appealing to eco-conscious consumers and meeting increasingly strict environmental regulations regarding single-use plastics.

2. Technical Specifications: Alloys, Tempers, and Thickness

When ordering custom aluminum foil food containers, vague requests like “standard size” often lead to dissatisfaction. To ensure the product meets your machinery and durability requirements, you must specify the material grade.

Common Alloys: 3003 vs. 8011

The two primary aluminum alloys used in container manufacturing are 8011 and 3003.

- Alloy 8011: This is the most common alloy for standard household foil and general-purpose takeaway containers. It offers excellent ductility, allowing it to be deep-drawn into complex shapes without tearing. It is cost-effective and sufficient for most bakery and catering applications.

- Alloy 3003: This alloy contains manganese, making it approximately 20% stronger than 8011. It is often preferred for larger, heavy-duty containers (like full-size steam table pans) or applications requiring higher rigidity. If your containers need to support heavy loads without buckling during transport, specifying 3003 is a wise move.

Temper and Hardness

Foil used for containers typically comes in H22 or H24 tempers.

- H22: Partially annealed and strain-hardened. It is slightly softer, making it ideal for containers with intricate designs or deep draws.

- H24: Harder and more rigid. This is better for shallow trays or lids where structural stiffness is prioritized over formability.

Thickness (Gauge)

Thickness is measured in microns (µm). The wholesale market sees a wide range, typically between 30µm and 80µm for semi-rigid containers.

- 30–45 microns: Standard takeaway trays and small tart pans. Lightweight and economical.

- 50–65 microns: Premium bakery trays and medium-sized meal containers. Provides a “quality feel” and resists denting.

- 70+ microns: Heavy-duty roasting pans and large catering trays. Essential for holding heavy volumes of liquid or dense meats.

3. Structural Options: Rims, Compartments, and Shapes

The structural design of the container dictates how it interacts with lids and how it performs during transport. Customization often starts here.

Rim Styles for Sealing and Lidding

The rim is not just an aesthetic feature; it determines the sealing method.

- Full Curl (FC): A rolled edge that provides rigidity and safety (no sharp edges). Ideal for foil board lids or plastic dome lids that snap over the edge.

- Interrupted Vertical Curl (IVC): Similar to full curl but designed specifically for plastic dome lids to grip securely.

- Hemmed Edge / Vertical Flange: A flat flange typically used for heat-sealing films. If you are using an automated heat-sealing machine for ready meals, a flat flange is mandatory to ensure an airtight hermetic seal.

Compartmentalization

For “bento” style meals or airline catering, multi-compartment containers (2, 3, or 4 cavities) are essential to keep sides and mains separate. Manufacturing these requires precise tooling to ensure the dividers are high enough to prevent spill-over but strong enough not to collapse.

4. Customization: Printing, Coloring, and Embossing

One of the most common questions from brand owners is: “Can I print my logo on the foil container?” The answer is yes, but with specific technical constraints compared to paper or plastic.

Lacquered Colors

Printing high-resolution images directly onto the wrinkled sidewalls of a formed foil container is generally not feasible. Instead, manufacturers use colored lacquers.

- Gold and Black: These are the most popular premium options. A gold-lacquered interior or exterior elevates the perceived value of the product, often used for high-end pâtisserie or holiday specials.

- Brand Colors: You can request specific Pantone-matched lacquers for the exterior walls. This coating must be heat-resistant and food-safe.

Embossing

For branding the container itself, embossing is the standard method. Your logo is engraved into the mold, creating a raised relief on the bottom of the container. This is a subtle, permanent, and premium way to brand without using inks. It requires a one-time tooling fee for the custom mold but adds zero unit cost to production.

Lid Customization

The primary real estate for branding is the lid.

- Paper-Alu Lids: Cardboard laminated with foil. These can be printed with full-color (CMYK) offset printing, allowing for vibrant photos, nutritional info, and barcodes.

- Heat Seal Films: Flexible films sealed to the top of the tray. These can be rotogravure printed for high-impact graphics.

5. Coatings and Grease Resistance

While aluminum is naturally impermeable, coatings play a vital role in food interaction.

Lubrication vs. Dry

During the stamping process, food-grade oils are used to lubricate the foil as it passes through the press. Standard containers will have a slight residue of this oil (which is food safe). For specific applications, you can request “dry” containers, though this may affect the depth of draw achievable.

Protective Lacquers

For acidic foods (like tomato-based lasagna or fruit tarts), uncoated aluminum can sometimes oxidize, leading to discoloration or a metallic taste. In these cases, a protective internal lacquer (often clear or white) is applied to prevent the food from reacting with the aluminum. Always specify if your product is highly acidic or salty.

6. Quality Control and Compliance

When sourcing aluminum foil food containers wholesale, verifying quality is non-negotiable. Defective batches can cause leaks, machinery jams, or food safety recalls.

Key Quality Tests

- Leakage Testing: Random samples should be filled with liquid and checked for pinholes. Even microscopic holes compromise the sterile barrier.

- Stacking Strength: Containers must unstack easily (denesting) without sticking together. If they stick, they will jam automated filling lines.

- Rim Dimensions: The rim diameter must be within strict tolerances to ensure lids fit securely.

Regulatory Standards

Ensure your supplier adheres to FDA (US) or LFGB (Europe) standards for food contact materials. The oils and lacquers used must be certified food-grade. Ask for compliance documentation before placing your first bulk order.

7. Ordering Guide: MOQs, Lead Times, and Logistics

Navigating the logistics of wholesale ordering requires planning.

Minimum Order Quantities (MOQ)

Because foil containers are produced on high-speed presses (thousands per hour), MOQs are typically high.

- Standard Stock Items: May have lower MOQs (e.g., 10,000–50,000 units).

- Custom Embossed/Colored Items: Often require MOQs of 100,000+ units to justify the setup and coating runs.

Molds and Tooling

If you need a custom size that doesn’t match an existing mold, you will need to pay for a new die. This is a significant upfront investment ($1,000–$5,000+ depending on complexity) but pays off for high-volume unique products. Always ask if the manufacturer has a “public mold” list to avoid these fees.

Shipping and Storage

Foil containers are lightweight but voluminous (“cubed out”). They stack efficiently, but they are fragile. Cartons must be rigid to prevent crushing the bottom layers. Store them in a dry, climate-controlled environment to prevent oxidation or moisture damage to paper dividers.

For detailed steps on initiating an order, visit our How to Order page.

8. Common Use Cases and Selection Checklist

To summarize, here is how different industries typically configure their orders:

| Industry | Typical Container Style | Key Feature |

|---|---|---|

| Bakery | Round tart pans / Loaf pans | H22 Temper (softer), often colored gold/black. |

| Ready Meals | Rectangular multi-compartment | Heat-sealable flange for film sealing. |

| Roasting/Catering | Large deep rectangular | Heavy gauge (70µm+), Alloy 3003 for strength. |

| Takeaway | Standard rectangular | Full curl rim for paper-foil lids. |

9. Frequently Asked Questions (FAQ)

Q1: Can aluminum foil containers be used in the microwave?

Yes, modern aluminum foil containers can be used in microwaves designed after the 1980s, provided the container is filled at least 2/3 with food, placed in the center of the turntable, and does not touch the walls of the microwave. However, always consult the manufacturer’s specific usage guidelines.

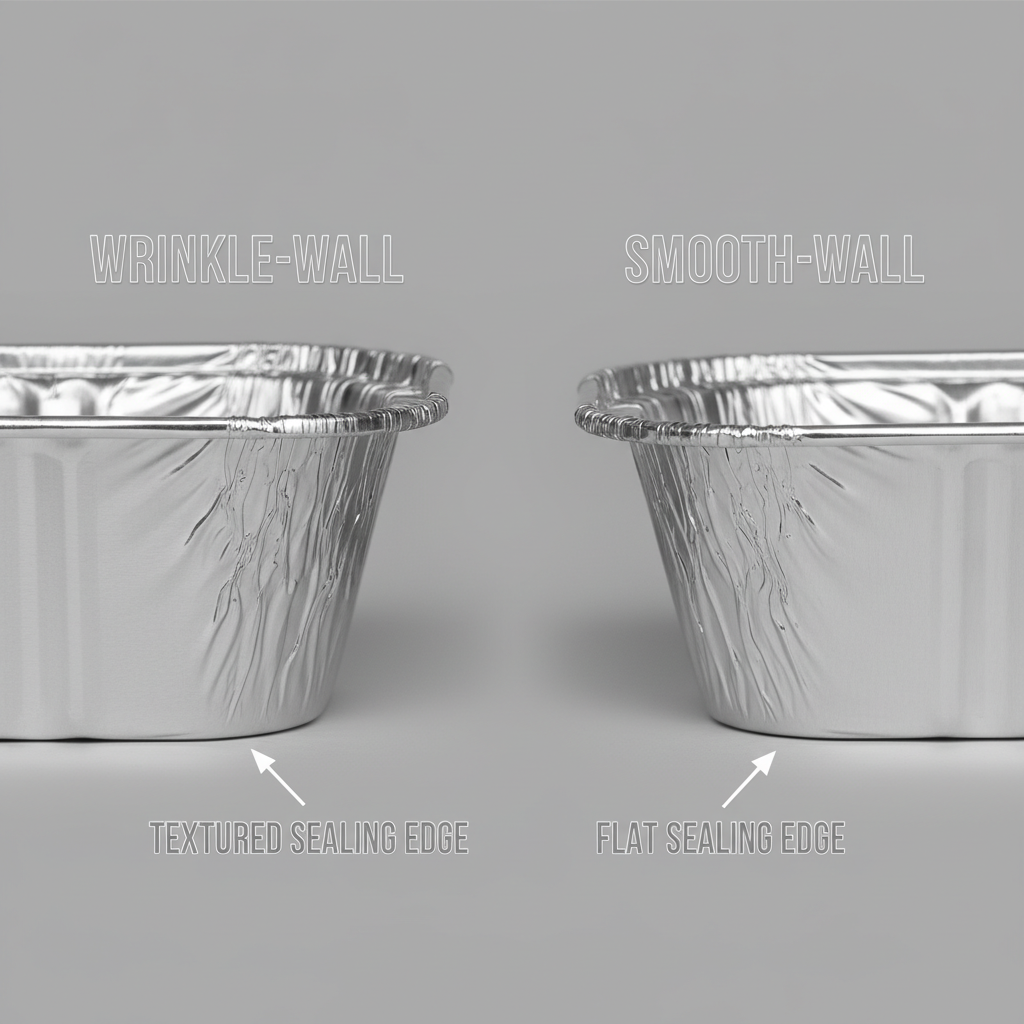

Q2: What is the difference between a “wrinkle wall” and a “smooth wall” container?

Wrinkle wall containers are formed by pressing foil into a mold, resulting in pleated sides. They are cheaper and lighter. Smooth wall containers are drawn under high pressure to create smooth sides and a flat rim, ideal for heat sealing and high-end presentation (similar to rigid plastic).

Q3: How do I submit artwork for a custom printed lid?

Artwork should be submitted in vector format (AI, PDF, EPS). Ensure you have the correct die-line template from the manufacturer before designing. Be aware of color limitations if printing on foil versus paper.

Q4: Are colored foil containers food safe?

Yes, provided the lacquers used are food-grade and heat-resistant. They are applied to the outside (and sometimes inside) and cured at high temperatures to ensure they do not migrate into food.

Q5: Can I get a sample before ordering 100,000 units?

Absolutely. Reputable suppliers will provide samples of existing sizes. For custom molds, you may receive a 3D prototype or a pilot run sample, though this may incur costs.

Q6: What is the lead time for a custom order?

Standard items can often ship within 1-2 weeks. Custom orders (new molds or custom printing) typically require 4-6 weeks: 2 weeks for tooling/artwork approval and 3-4 weeks for production and packaging.

Conclusion

Sourcing custom aluminum foil food containers is a strategic move for businesses looking to combine durability, aesthetics, and sustainability. By understanding the nuances of alloys, rim styles, and printing options, you can tailor your packaging to enhance your brand and protect your product.

At YBJ Packing, we specialize in helping international buyers navigate these specifications to find the perfect packaging solution. Whether you need a standard wholesale batch or a fully customized container with embossed branding, our team is ready to assist.

Ready to elevate your food packaging? Request a quote today or contact our engineering team to discuss your specific requirements.