Introduction: The Strategic Importance of Cake Packaging

For industrial bakeries, restaurant chains, and food distributors, the cake box is not merely a container; it is a critical component of product integrity and brand equity. In the B2B food service sector, the packaging must perform a dual function: it must engineer the safe transport of delicate, high-value confectionery products, and it must serve as a mobile billboard for the brand. A collapsed box or a grease-stained exterior can result in product loss, returns, and significant reputational damage.

Procurement managers and packaging engineers face a complex array of decisions when sourcing cake boxes. From selecting the correct paperboard substrate to determining the optimal flute profile for heavy tiered cakes, technical specifications matter. This guide provides a comprehensive analysis of materials, structural designs, printing technologies, and supply chain considerations for wholesale buyers.

1. Material Selection: The Technical Foundation

The structural integrity of a cake box depends entirely on the base material. Unlike general retail packaging, food packaging requires materials that are not only strong but also food-safe and resistant to moisture and grease.

Solid Bleached Sulfate (SBS) / Ivory Board

SBS, often referred to as Ivory Board in certain markets, is the premium standard for custom cake boxes. It is produced from bleached virgin wood pulp, resulting in a clean, white surface throughout the sheet (top, middle, and back).

- Characteristics: High brightness, excellent surface smoothness for printing, and superior stiffness-to-weight ratio.

- Typical Grammage: 300gsm to 400gsm.

- Use Case: Single-layer cakes, pastries, and premium branding where vibrant print quality is required. The white surface provides the best canvas for CMYK offset printing.

Coated Unbleached Kraft (CUK) / Kraft Board

Kraft board is engineered from unbleached wood pulp, retaining the natural brown color of the wood fibers. It is increasingly popular for brands emphasizing sustainability and organic ingredients.

- Characteristics: High tear resistance and tensile strength. The long fibers in the unbleached pulp provide exceptional durability.

- Typical Grammage: 250gsm to 450gsm.

- Use Case: Rustic-themed bakeries, heavy fruit cakes, and eco-conscious brands. While print vibrancy is lower than SBS, it communicates an “all-natural” aesthetic effectively.

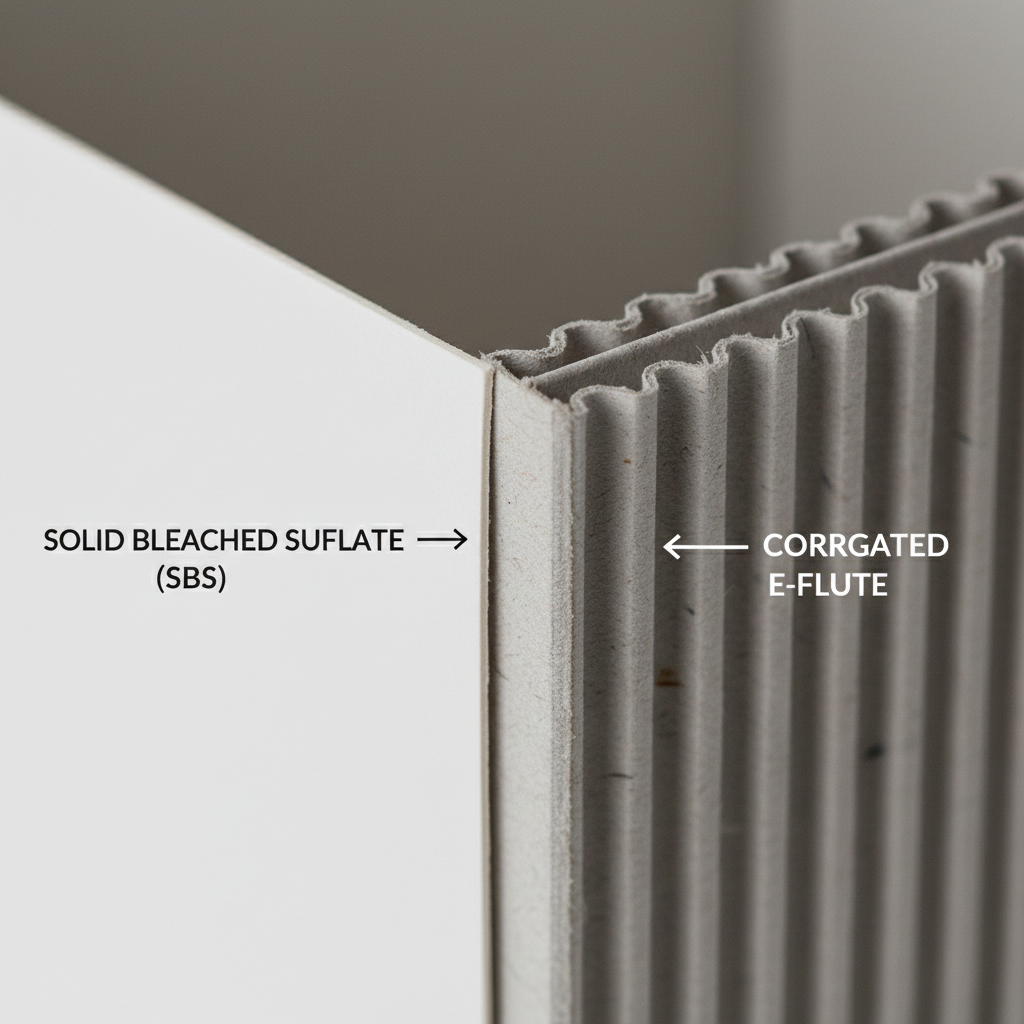

Corrugated Fiberboard (E-Flute and F-Flute)

For larger cakes, wedding cakes, or bulk transport, standard paperboard often lacks the necessary vertical compression strength. Corrugated board—consisting of a fluted medium sandwiched between two liners—is the solution.

- E-Flute (1.1mm – 1.6mm thick): The most common flute for heavy cake boxes. It offers a smooth surface for litho-lamination (where a printed sheet is glued to the corrugated board) while providing significant stacking strength.

- F-Flute (0.8mm thick): A micro-flute option that bridges the gap between folding cartons and corrugated boxes. It provides better printability than E-flute but slightly less cushioning.

- Use Case: Tiered cakes, heavy cheesecakes, and delivery-focused business models where boxes may be stacked during transport.

Duplex Board with Grey Back

This is a cost-effective material consisting of a white coated top layer and a recycled grey fiber backing. While economical, it is generally less stiff than virgin fiber boards and requires a food-safe barrier if in direct contact with food.

- Use Case: High-volume, cost-sensitive wholesale packaging where the cake sits on a separate board or tray.

2. Grease Resistance and Barrier Coatings

Cakes, particularly those with buttercream, ganache, or high oil content, pose a risk of grease migration. If the packaging material is absorbent, oil spots will appear on the exterior, ruining the visual appeal. To prevent this, specific coatings are applied.

Polyethylene (PE) Coating

A thin layer of polyethylene is extruded onto the inner surface of the paperboard. This creates a physical barrier against moisture and grease.

- Pros: Highly effective against oil; heat sealable.

- Cons: Can complicate recycling processes in some regions (requires separation facilities).

Aqueous Coatings and Varnishes

Water-based coatings can be applied during the printing process. While they offer some surface protection, they are generally less resistant to heavy grease than PE linings. They are often used on the exterior to protect the ink.

Vegetable-Based Barriers

Newer innovations include dispersion coatings that are plastic-free and biodegradable, offering moderate grease resistance suitable for drier cakes or those already on a cake board.

3. Structural Design and Sizing Guide

The geometry of the box dictates the user experience (assembly speed) and product safety. Buyers must balance aesthetic presentation with logistics efficiency.

Common Structural Styles

- Lock Bottom (Auto-Lock): The bottom flaps interlock automatically when the box is popped open. This is critical for high-volume bakeries as it reduces assembly time by seconds per unit.

- Six-Corner Beers Style: A tray style often used for donuts or sheet cakes, where the corners fold in and lock.

- Two-Piece (Telescope Lid): A separate lid and base. This is the traditional style for premium cakes. It allows the consumer to remove the lid and slide the cake out without reaching inside.

- Handle Boxes: Integrated handles (gable boxes) are popular for takeaways. However, the material must be heavy enough to support the cake’s weight at the handle stress points.

Window Patching

Visibility drives sales. A clear window allows the product to be seen without opening the box. The window material is typically PET (Polyethylene Terephthalate) or PP (Polypropylene), glued to the inside of the die-cut opening. For high-end applications, ensure the window film is anti-fog to prevent condensation from obscuring the view of fresh cakes.

Sizing Considerations

When ordering food packaging boxes, internal dimensions are the standard metric. A common error is ordering a box that fits the cake exactly, leaving no room for handling.

- Clearance Rule: Always add at least 1 inch (2.54 cm) to the diameter of the cake board (not just the cake) to allow for finger clearance when inserting and removing the product.

- Height: Measure the tallest point of the decoration. For tiered cakes, custom height extenders or specialized tall boxes are necessary.

4. Printing and Customization Options

Customization transforms a commodity item into a brand asset. Understanding printing technologies helps in optimizing costs and quality.

Offset Printing (Lithography)

The industry standard for high-quality bulk orders.

- Process: Ink is transferred from a plate to a rubber blanket, then to the paper.

- Advantages: Superior image quality, accurate color reproduction (CMYK + Pantone), and cost-effective for large runs (typically 1,000+ units).

- Finishes: Compatible with a wide range of finishes like UV coating, matte lamination, and soft-touch varnish.

Flexographic Printing

Often used for simple logos on corrugated boxes or kraft bags.

- Process: Uses flexible relief plates.

- Advantages: Lower tooling costs than offset; works well on rough surfaces like corrugated board.

- Limitations: Not suitable for high-resolution photo-realistic images.

Finishing Techniques

- Hot Foil Stamping: Applying metallic foil (gold, silver, rose gold) using heat and pressure. Adds a premium, luxury feel.

- Embossing/Debossing: Raising or recessing parts of the design (like a logo) for tactile effect.

- Spot UV: Applying a high-gloss varnish to specific areas (e.g., the logo) against a matte background for contrast.

5. Manufacturing and Quality Assurance

Reliable manufacturing ensures that every box performs as expected on the assembly line and in transit.

Die-Cutting Precision

The die-cutting process creates the shape of the box. Poor tooling can result in ragged edges or score lines that are too deep (causing cracking) or too shallow (making folding difficult). Precision is vital for auto-lock bottoms to function correctly.

Gluing Strength

For pre-glued boxes, the adhesive must be food-safe and capable of withstanding temperature variations (e.g., from a hot bakery to a refrigerated display). Failure in the glue line is a critical defect.

Food Safety Compliance

Manufacturers should adhere to Good Manufacturing Practices (GMP). Materials in direct contact with food must comply with relevant regulations (such as FDA 21 CFR or EU 1935/2004) regarding the migration of substances. Always confirm that the inks and glues used are low-migration and safe for indirect food contact.

6. Buyer’s Guide: How to Order Efficiently

Sourcing packaging involves logistical and financial planning. Here is a checklist for B2B buyers.

Minimum Order Quantity (MOQ)

Custom manufacturing requires setup time (plate making, die preparation). Consequently, MOQs are typically required to amortize these costs.

- Small Run (500-1,000 units): Higher unit cost, often digital or simple offset.

- Standard Run (5,000-10,000 units): Optimal balance of unit price and inventory cost.

- Mass Production (50,000+ units): Lowest unit cost, requires significant warehousing space.

Artwork Preparation

To ensure the final product matches your vision:

- Vector Files: Provide logos in AI, EPS, or PDF format.

- Bleed Lines: Ensure artwork extends beyond the cut line (usually 3mm) to avoid white edges.

- Color Codes: Specify Pantone (PMS) codes for brand colors to ensure consistency across different print runs.

Lead Times

Custom packaging is not an off-the-shelf product. Typical timelines include:

- Design & Sampling: 5-10 days.

- Production: 15-25 days depending on complexity and quantity.

- Shipping: Variable based on air vs. sea freight.

For urgent launches, discuss expedited options early in the negotiation process.

Logistics and Storage

Cake boxes are shipped flat (knocked down) to save space. However, corrugated boxes take up more pallet space than solid board boxes. Calculate your warehouse capacity before ordering a 6-month supply. Ask for palletization specifications to ensure compatibility with your forklifts and racking systems.

7. Common Use Cases and Recommendations

| Product Type | Recommended Material | Recommended Style | Key Feature |

|---|---|---|---|

| Standard Birthday Cake (8-10″) | SBS Board (350gsm) | Lock Bottom with Window | Easy assembly, product visibility |

| Heavy Wedding Cake (2+ Tiers) | E-Flute Corrugated | Separate Lid & Base | High load-bearing strength |

| Cupcakes (Set of 6/12) | SBS or CUK Board | Box with Insert | Insert prevents movement/toppling |

| Artisanal/Organic Cake | Kraft Board (Unbleached) | Gable Box (Handle) | Eco-friendly aesthetic, portable |

| Swiss Rolls / Log Cakes | SBS Board (300gsm) | Long Rectangular Side-Open | Easy side-loading |

8. Frequently Asked Questions (FAQ)

Q1: How do I measure a cake box correctly?

Measure the Length (L) x Width (W) x Depth (D) of the interior of the box. Always match these dimensions to your cake board size plus clearance, not just the cake itself.

Q2: Can I print inside the cake box?

Yes, inside printing is possible and adds a premium unboxing experience. However, the ink used must be food-safe (often soy-based) or the inside must be coated/laminated to prevent direct contact between the cake and the ink.

Q3: What is the difference between “folding carton” and “corrugated box” for cakes?

Folding cartons are made from a single layer of thick paperboard (like a cereal box but thicker). They are suitable for lighter cakes. Corrugated boxes have fluting (layers) and are much stronger, suitable for heavy or tiered cakes.

Q4: Are window patches recyclable?

Standard PET windows are plastic. If the box is to be recycled, the consumer usually needs to remove the plastic window. Some manufacturers offer PLA (corn starch) windows which are compostable, though they may have lower clarity and heat resistance.

Q5: How can I test if a box is strong enough for my cake?

We recommend requesting a plain sample. Place a dummy weight (equal to your heaviest cake) inside and test lifting it by the base and handles (if applicable). Keep it in a refrigerator for 24 hours to see if humidity affects the board stiffness.

Q6: Does lamination affect the recycling of the box?

Gloss or matte lamination usually involves a thin plastic film. This can make recycling more difficult compared to non-laminated boxes or those with aqueous varnish. If sustainability is a priority, ask for water-based coatings instead of film lamination.

Q7: What file format is needed for the logo?

Vector formats like .AI (Adobe Illustrator) or .PDF are required for crisp printing. Raster images (JPEG, PNG) will pixelate when enlarged and are not suitable for high-quality packaging printing.

Conclusion

Selecting the right cake box is a balance of engineering, aesthetics, and economics. For B2B buyers, understanding the nuances of paper grades, coatings, and structural design ensures that the final product protects the cake while enhancing the brand.

Whether you need a robust corrugated solution for heavy tiered cakes or a sleek, windowed ivory board box for retail display, YBJ Packing offers a range of customization options to meet specific operational requirements. From material sourcing to high-fidelity printing, our manufacturing capabilities are designed to support your supply chain.

Ready to upgrade your packaging? Contact our team today to discuss your specifications, or visit our How to Order page to start your custom project. We are happy to provide samples to ensure your packaging meets the highest standards of quality and functionality.