The Critical Role of Packaging in the Pizza Business

In the competitive landscape of the food service industry, the pizza box is more than just a container; it is a mobile billboard, a thermal insulator, and a structural guardian of your product. For pizzerias, restaurant chains, and food distributors, sourcing the right custom pizza paper box wholesale is a strategic decision that impacts customer satisfaction and brand perception.

When a customer orders a pizza, the packaging is often the only physical touchpoint they have with your brand outside of the food itself. A flimsy box that collapses under the weight of a deep-dish pie, or a material that allows grease to soak through onto a customer’s table, can ruin the dining experience regardless of how delicious the pizza is. Conversely, a sturdy, well-vented, and beautifully printed box enhances perceived value and keeps the product at optimal temperature and texture.

This comprehensive guide explores the technical specifications, material options, printing technologies, and procurement strategies necessary for sourcing high-quality pizza boxes in bulk. Whether you are upgrading your current packaging or launching a new franchise, understanding these details will help you make informed purchasing decisions.

1. Material Selection: The Foundation of a Quality Box

The structural integrity of a pizza box depends entirely on the material used. While “cardboard” is the generic term, industrial buyers must choose between specific grades of paperboard and corrugated fiberboard to balance cost, strength, and insulation.

Corrugated Fiberboard (The Industry Standard)

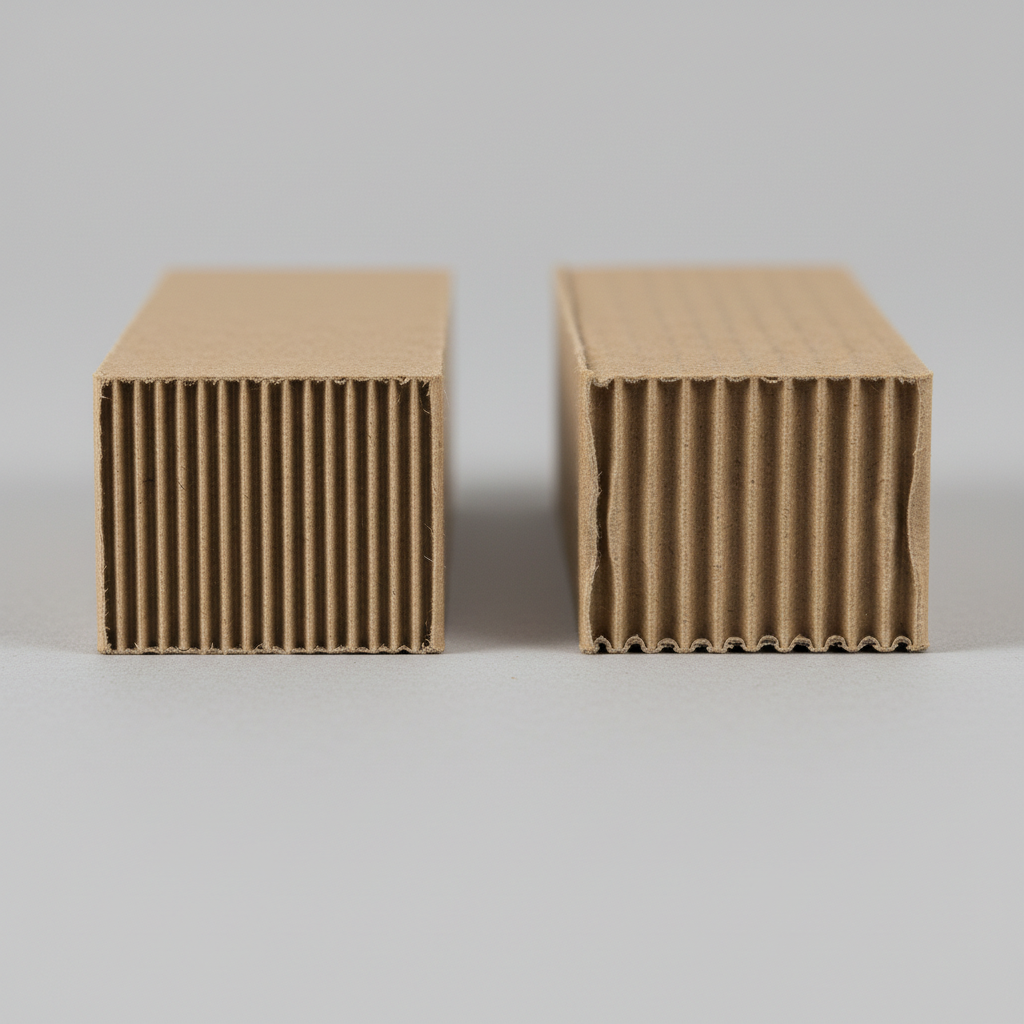

Most pizza boxes are manufactured from corrugated fiberboard due to its excellent strength-to-weight ratio and insulation properties. Corrugated board consists of a fluted (wavy) sheet sandwiched between two flat linerboards.

- E-Flute: The most common profile for pizza boxes. It is approximately 1.6mm thick. E-flute offers a smooth surface for printing and sufficient rigidity for standard pizzas without being overly bulky. It stores well and folds easily.

- B-Flute: Thicker than E-flute (approx. 3mm). This is often used for heavy, large-diameter pizzas (18 inches and up) or deep-dish styles that require extra stacking strength during delivery.

Solid Bleached Sulfate (SBS) & Folding Carton

For smaller items like individual slices, calzones, or frozen pizza retail packaging, thinner folding carton materials are often used. These do not have the insulating air pockets of corrugated board but offer a smoother surface for high-resolution printing.

Kraft vs. White Linerboard

The linerboard is the outer surface of the box. Your choice here affects both aesthetics and printing costs.

- Brown Kraft: Unbleached and naturally brown. It conveys an eco-friendly, rustic, or artisanal image. It is generally more cost-effective. However, printing colors on brown kraft can appear darker or less vibrant.

- White Top / Bleached: A white outer liner provides a clean canvas for logos and graphics. Colors pop more vividly on white backgrounds. This is preferred for brands with complex color palettes or those seeking a modern, sanitary look.

To explore the specific material grades available for your region or product type, review our catalog of pizza paper boxes.

2. Grease Resistance and Food Safety

One of the biggest challenges in pizza packaging is grease migration. Hot cheese and meats release oils that can quickly saturate untreated paper, leading to unsightly stains and weakened structural integrity.

Food-Grade Coatings

To prevent soak-through, manufacturers apply barriers to the inner liner of the box. It is vital to specify that these coatings must be food-grade and compliant with relevant safety standards (such as FDA or EU regulations) for direct food contact.

- Clay Coating: Provides a smooth surface and moderate grease resistance.

- Aqueous Coating: A water-based coating that seals the paper fibers.

- Wax Alternative / Sizing: Traditional wax coatings render boxes non-recyclable. Modern manufacturing prefers specialized sizing agents or eco-friendly barriers that repel oil while remaining repulpable in recycling facilities.

Paper Quality and Virgin vs. Recycled Fibers

For direct food contact, the inner liner is often made from virgin kraft fibers to ensure purity and high tear resistance. Recycled fibers are commonly used for the fluting (middle layer) and outer liner to reduce environmental impact and cost. When sourcing wholesale food packaging, always verify that the inner surface meets hygiene requirements for hot food applications.

3. Structural Design and Engineering

A pizza box is an engineered product. Its design determines how well it stacks, vents steam, and locks closed.

Venting Systems

Steam is the enemy of a crispy crust. If a box is sealed too tightly, trapped steam condenses and drips back onto the pizza, making it soggy. If it vents too much, the pizza gets cold.

Effective design includes strategically placed vent holes or slots—usually on the back side or corners—to allow excess moisture to escape while retaining heat. The size and shape of these vents can be customized, but standard die-cut patterns are usually sufficient for most dough types.

Corner Construction

The corners are the load-bearing pillars of the box. When delivery drivers stack five or ten pizzas, the bottom box must support the weight without crushing the food inside.

- Standard Lock Corners: The most common style, where tabs lock into slots.

- Glued Corners: Pre-glued 4-corner or 6-corner boxes can be set up faster by restaurant staff, saving seconds during the rush hour. However, they may require more storage space or different shipping configurations.

Stacking Strength (ECT)

For wholesale buyers, asking about the Edge Crush Test (ECT) rating can be beneficial. A standard pizza box should have enough vertical compression strength to handle the rigors of delivery logistics. If you frequently experience crushed box tops, consider upgrading to a higher ECT rating or a thicker flute profile.

4. Custom Printing Options

Branding is a primary driver for custom packaging. The printing method you choose will depend on your order volume, budget, and artwork complexity.

Flexographic Printing (Flexo)

This is the industry standard for shipping boxes and pizza boxes. It uses flexible relief plates to transfer ink onto the board.

Pros: Very cost-effective for high volumes; fast production speeds.

Cons: Lower resolution compared to offset; usually limited to 1-4 spot colors. Gradients and photo-realistic images are difficult to achieve.

Best For: Simple logos, bold text, and 1-2 color designs on large wholesale orders.

Offset Lithography (Litho-Lamination)

For premium boxes, the artwork is printed on a separate sheet of paper (label) using offset printing, which is then laminated onto the corrugated board.

Pros: Magazine-quality print; full CMYK color range; capability for photos and complex gradients.

Cons: Higher tooling and setup costs; higher Minimum Order Quantities (MOQs) usually required to make it economical.

Best For: Gourmet frozen pizzas, promotional marketing kits, or high-end franchise branding.

Digital Printing

Direct-to-board digital printing is growing in popularity for short runs.

Pros: No plate costs; quick turnaround; easy to change designs (e.g., for seasonal promotions).

Cons: Higher per-unit cost for large volumes.

Best For: Limited time offers, samples, or small local chains.

5. Sizing Guide: Matching the Box to the Pie

Standardization helps reduce costs. While custom sizes are possible, sticking to industry-standard dimensions usually results in better pricing and easier procurement of related items (like pizza liners or tripods).

Common Square Box Sizes:

- 8-9 inch: Personal pan pizzas, small gluten-free crusts, or large cookies/brownies.

- 10-12 inch: Small to Medium pizzas. Standard for many authentic Neapolitan styles.

- 14-16 inch: Large to Extra Large. The workhorse size for most delivery chains.

- 18-20+ inch: “Jumbo” or “Party” sizes. These require stronger board (B-flute) to prevent sagging.

Height Considerations:

Standard height is often around 1.5 to 1.75 inches (approx 4-4.5 cm). If you serve deep-dish Chicago style or pizzas with generous toppings, ensure you request a taller box (2 inches / 5 cm or more) to prevent the lid from touching the cheese.

If you are sourcing a variety of food packaging boxes, standardizing your footprint where possible can also optimize your warehouse storage.

6. Sustainability and Environmental Trends

Modern consumers are increasingly conscious of packaging waste. B2B buyers must consider the end-of-life of the packaging.

- Recyclability: Corrugated board is highly recyclable. However, heavy grease contamination can make it unfit for recycling streams in some municipalities. Using a separate grease-proof liner paper inside the box can keep the box cleaner and more recyclable.

- Compostability: Uncoated, unbleached kraft boxes printed with soy or water-based inks are often commercially compostable.

- Recycled Content: Specifying a high percentage of post-consumer waste (PCW) in your corrugated board is a strong selling point for eco-conscious brands.

7. Wholesale Buying Guide: Logistics & Ordering

Ordering custom pizza boxes involves more than just picking a design. Logistics play a huge role in the total landed cost.

Minimum Order Quantities (MOQ)

Custom manufacturing requires setup time for corrugators, die-cutters, and printing plates. Consequently, factories set MOQs.

For flexo printing, MOQs might start at 5,000 or 10,000 units. For high-end offset printing, MOQs may be higher. Ordering in full container loads (FCL) drastically reduces the unit price compared to less-than-container loads (LCL).

Flat Packing and Storage

Pizza boxes are shipped flat (knocked down) to maximize shipping volume.

Tip: Ensure your warehouse has a dry, climate-controlled area for storage. Corrugated board is hygroscopic; if stored in high humidity, it absorbs moisture and loses stacking strength before it is even folded.

Lead Times

Custom production typically takes 2-4 weeks after artwork approval, plus transit time. International shipping can add several weeks. Always plan your inventory replenishment to account for these timelines, especially ahead of major events (like the Super Bowl or holidays).

Sampling

Before committing to a full production run, request a plain sample to test the size and material strength. Then, request a printed proof (digital or physical) to verify logo placement and color accuracy.

For details on how to initiate a custom order, please visit our ordering guide.

8. Troubleshooting Common Issues

If you are experiencing issues with your current packaging, use this checklist to identify the specification change needed:

- Problem: Box collapses when stacked.

Solution: Upgrade to a higher ECT rating or switch from E-flute to B-flute. - Problem: Pizza arrives cold.

Solution: Check if vents are too large or too numerous. Ensure the box closes tightly. - Problem: Pizza arrives soggy.

Solution: Insufficient venting. Add vent holes to the design. - Problem: Grease stains on the outside.

Solution: The linerboard lacks sufficient sizing or coating. Request a grease-resistant inner liner or use a separate parchment insert. - Problem: Ink rubs off.

Solution: Ensure the manufacturer uses cured, rub-resistant inks and that the coating is compatible with the ink type.

9. Frequently Asked Questions (FAQ)

Q1: Can I print on the inside of the pizza box?

Yes, printing on the inside lid is a popular trend for revealing messages or promo codes as the customer opens the box. However, this requires food-safe inks (usually water-based or soy-based) and may increase the cost.

Q2: What is the difference between E-flute and B-flute?

E-flute is thinner (approx 1.6mm) and prints better, making it the standard for most pizza boxes. B-flute is thicker (approx 3mm) and stronger, used for very large or heavy pizzas.

Q3: Do I need to pay for printing plates?

Yes, for Flexo and Offset printing, there is a one-time setup fee for the printing plates. Once paid, you typically do not pay this again for reorders unless the artwork changes.

Q4: How do I know what size box I need?

Measure the diameter of your baked pizza. The box inner dimensions should be roughly 0.25 to 0.5 inches larger than the pizza to prevent sliding without wasting space.

Q5: Are custom shapes available?

Yes, manufacturers can create custom die-lines for octagonal boxes, slice boxes, or unique locking mechanisms. This requires a one-time cutting die fee.

Q6: Can you match my brand colors exactly?

Using the Pantone Matching System (PMS), manufacturers can match specific spot colors. However, colors may look slightly different on brown kraft material versus white material.

Conclusion

Sourcing the right pizza box balances thermal performance, brand aesthetics, and cost efficiency. By understanding the nuances of flute profiles, paper grades, and printing techniques, you can communicate effectively with suppliers and secure packaging that protects your product and promotes your brand.

At YBJ Packing, we specialize in high-quality, custom-printed food packaging solutions for the global market. Whether you need a standard kraft box or a high-gloss full-color container, our team can guide you through the specifications to find the perfect fit for your operation.

Ready to upgrade your pizza packaging? Contact us today to request a quote or get a sample of our custom pizza paper boxes.