Why Grease Resistance Matters in Food Packaging

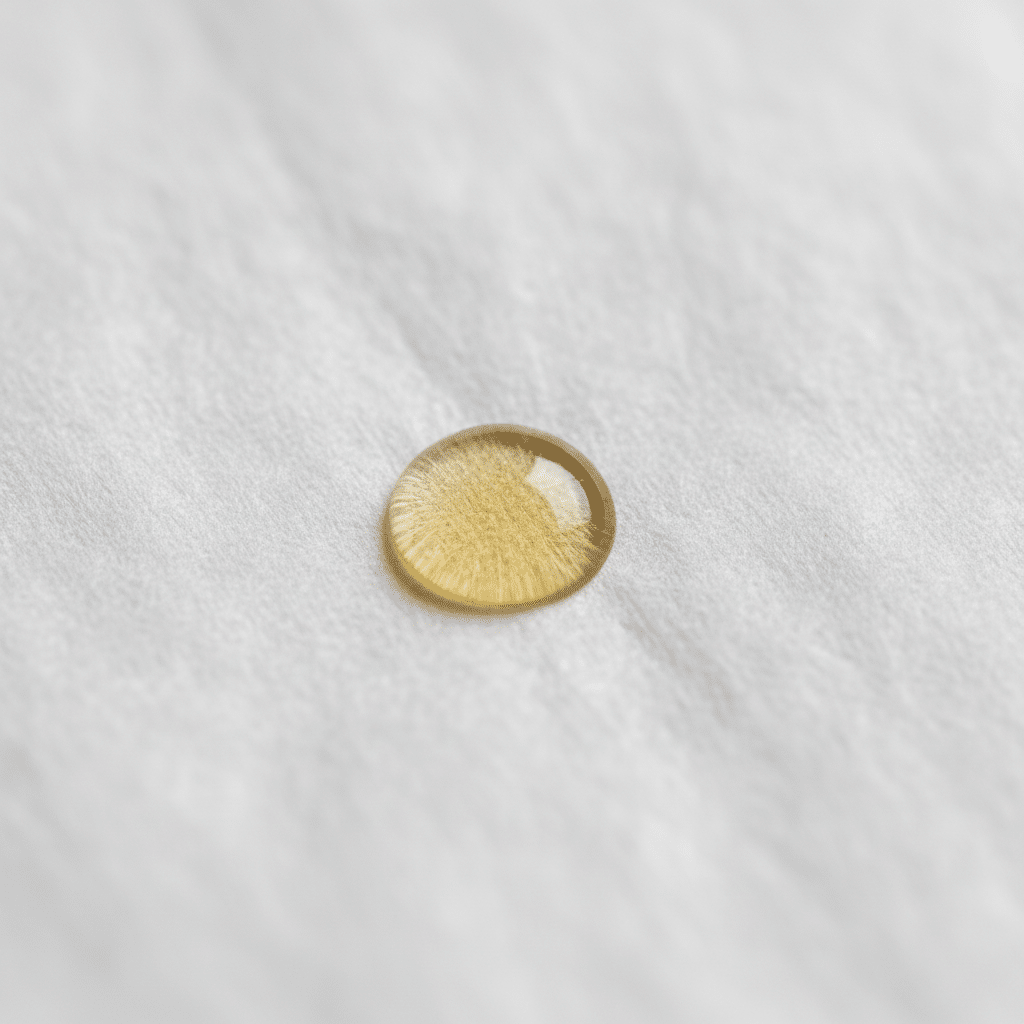

For vendors selling fried chicken, french fries, or buttery pastries, packaging is more than just a container; it is a critical component of the customer experience. A bag that succumbs to oil saturation not only stains the customer’s hands and clothes but also degrades the structural integrity of the package, leading to tears and spills.

In the B2B packaging sector, selecting the correct greaseproof paper bags is a balance between oil resistance, breathability, and cost. High-quality oil resistant packaging protects your brand image by ensuring food arrives looking appetizing and clean, whether it is served over the counter or delivered via a courier.

This guide covers the technical specifications, material options, and quality indicators procurement managers need to know when sourcing packaging for oily foods.

Understanding Greaseproof Technologies

Not all paper bags handle oil the same way. Understanding the underlying technology helps in specifying the right product for your menu items.

1. Chemical Treatment (The "Kit" Level)

Standard greaseproof paper is typically treated during the pulping process or coated to resist oil penetration. The industry standard for measuring this resistance is the Kit Test (TAPPI T 559). Kit levels range from 1 to 12, where 12 indicates the highest resistance to aggressive oils and solvents.

- Kit Level 1–3: Suitable for dry foods or items with very low fat content (e.g., bread loaves).

- Kit Level 4–6: Ideal for standard bakery items like cookies, muffins, or donuts (bakery bags).

- Kit Level 7–9: Required for deep-fried foods like french fries, hash browns, and fried chicken wings.

- Kit Level 10+: Used for extremely oily or prolonged contact situations.

2. PE (Polyethylene) Coating

For maximum hold-out, some bags use a thin layer of polyethylene (PE) laminated onto Kraft paper. While this provides a near-perfect barrier against grease and moisture, it significantly reduces breathability. This is excellent for preventing leaks in sauces or very greasy meats but can cause hot, crispy foods (like fries) to steam and become soggy if not properly vented.

Material Comparison: Which Bag for Which Food?

Selecting the right material depends on the fat content, temperature, and required shelf life of the food.

| Material Type | Best Application | Key Benefit | Trade-off |

|---|---|---|---|

| Standard Greaseproof Paper | Pastries, sandwiches, burgers | Breathable; keeps crusts crispy | May stain with heavy, hot oil over time |

| PE-Lined Kraft | Fried chicken buckets, wet sauces | 100% leak-proof barrier | Traps steam; less eco-friendly recycling |

| Wax-Coated Paper | Cold greasy foods, deli wraps | Excellent release properties | Wax can melt on hot foods |

Key Technical Specifications to Define

When requesting a quote for fried food packaging, specificity reduces the risk of receiving samples that fail in the field. Ensure your specification sheet includes:

Paper Weight (GSM)

Grammage (GSM) determines the bag’s rigidity. A standard french fry bag might use 40–50 GSM paper, whereas a larger bag holding a kilogram of fried chicken might require 70–80 GSM reinforced paper to prevent tearing under weight.

Breathability vs. Barrier

Fried foods release steam. If the bag is too sealed (like a PE-lined bag without vents), the steam condenses, turning crispy batter into mush. For items like fries or churros, unlined high-Kit greaseproof paper is often superior because it allows steam to escape while retaining the oil.

Food-Safe Inks

Branding is essential, but safety is paramount. Greaseproof wrapping paper and bags often come into direct contact with food. Ensure your supplier uses water-based or vegetable-based inks that are certified food-safe and resistant to bleeding when in contact with hot oil.

Quality Control and Testing

Before placing a bulk order, request samples to perform field tests. Laboratory data is useful, but real-world performance is definitive.

- The Stain Test: Place hot food in the bag and let it sit for 30 minutes. Check the exterior for dark spots or transparency.

- The Friction Test: Rub the printed area with a greasy napkin to ensure the ink does not smudge or transfer.

- The Heat Test: Ensure the glue lines hold up under the heat of freshly cooked food. Poor quality adhesives can soften and cause the bag bottom to open.

Buying Guide: Logistics and Customization

Minimum Order Quantities (MOQ)

Custom printed greaseproof paper bags usually carry an MOQ to justify the setup costs for flexographic or offset printing plates. MOQs typically range from 10,000 to 30,000 units depending on the complexity of the design and bag size. Stock sizes (plain) often have lower thresholds.

Lead Times and Storage

Production lead times for custom packaging can vary from 3 to 6 weeks. It is advisable to forecast demand accurately, especially before peak seasons. Greaseproof paper should be stored in a cool, dry environment; high humidity can affect the paper’s stiffness and the performance of the grease-resistant treatment over long periods.

Frequently Asked Questions

Can greaseproof bags be recycled?

Standard greaseproof paper (fluorochemical treated) is generally recyclable and compostable, provided it is not heavily soiled with food waste. PE-lined bags require specialized recycling facilities to separate the plastic liner from the paper fibers.

What is the difference between greaseproof and parchment paper?

Parchment paper is treated with acid to create high heat resistance and non-stick properties, primarily for baking. Greaseproof paper is designed specifically for packaging and serving, focusing on oil hold-out at a lower cost point.

Do you offer custom sizes for specific food items?

Yes, manufacturers can adjust dimensions (gusset width, height, opening) to fit specific products, such as long baguette bags or wide burger pouches.

Is white or brown Kraft paper better for grease resistance?

The base color (white bleached vs. brown unbleached) does not determine grease resistance; the treatment applied does. However, brown Kraft offers a more "natural" eco-friendly look, while white Kraft provides a better canvas for vibrant logo printing.

Secure Your Brand’s Quality

Don’t let poor packaging compromise the quality of your food. Choosing the right greaseproof paper bags ensures your customers enjoy their meal exactly as you intended—crispy, clean, and delicious.

Ready to upgrade your food packaging? Contact our team today to discuss your specific requirements, request material samples, or get a competitive quote for your bulk order.