In the high-stakes environment of commercial food service, packaging is not merely a vessel; it is a critical component of product quality control. For catering businesses, pizzerias, and industrial bakeries, the ability to maintain temperature, ensure structural integrity during transport, and minimize waste is paramount. Aluminum foil containers remain the industry standard for these applications due to their unique combination of thermal conductivity, mechanical strength, and recyclability.

This article examines the technical advantages of aluminum foil packaging in the food service sector, specifically focusing on heat retention dynamics, logistical benefits, and environmental considerations for procurement managers and business owners.

Thermal Dynamics: Conductivity and Heat Retention

One of the primary reasons aluminum foil containers dominate the catering and baking sectors is the material’s thermal properties. Aluminum is an excellent conductor of heat, which provides dual benefits depending on the stage of food preparation and delivery.

Uniform Baking and Cooking

For pizzerias and bakeries, uneven heat distribution can result in inconsistent product quality. Aluminum foil trays allow heat to distribute rapidly and evenly across the surface area of the container. This ensures that baked goods, lasagnas, and casseroles cook uniformly from the edges to the center, reducing the risk of burnt bottoms or undercooked middles.

Heat Retention During Transport

Once the food leaves the oven, the challenge shifts to heat retention. While aluminum is a conductor, when used in conjunction with proper lidding (such as foil-laminated board lids), these containers create an effective thermal barrier. This is critical for off-premise catering and food delivery services where maintaining a safe serving temperature (above 60°C / 140°F) is a food safety requirement.

Unlike plastic alternatives which may warp under high heat or insulate poorly, aluminum withstands extreme temperature fluctuations without degrading. This allows operators to take a dish directly from a freezer (-40°C) to an oven (up to 400°C) without transferring the food to a different vessel.

Structural Integrity and Logistics

Durability in transit is a major concern for B2B food distributors. Packaging failures lead to food waste, customer complaints, and operational losses. Aluminum foil containers offer a superior strength-to-weight ratio compared to paper or plastic alternatives.

Rigidity and Stackability

Aluminum containers are engineered with specific ribbing patterns on the sidewalls. These ribs are not merely aesthetic; they provide structural reinforcement that prevents the container from collapsing under the weight of heavy foods like dense pastas or meats. This rigidity allows for safe vertical stacking during transport, optimizing van space and reducing the number of trips required for large catering events.

Barrier Protection

Beyond physical strength, aluminum provides a total barrier against light, moisture, and oxygen. This is particularly important for pre-packaged meals intended for longer shelf lives. By preventing oxidation and moisture loss, the packaging helps maintain the flavor profile and texture of the food from the central kitchen to the final consumer.

Sustainability and the Circular Economy

As regulatory pressure mounts on single-use plastics, aluminum foil containers offer a compliant and sustainable alternative. Aluminum is infinitely recyclable without loss of properties. This distinction is crucial for businesses aiming to meet corporate social responsibility (CSR) goals or comply with regional packaging waste regulations.

- Recyclability: Unlike many plastics that are down-cycled into lower-grade products, aluminum can be melted down and reformed into new containers repeatedly.

- Resource Efficiency: Modern manufacturing processes have allowed for “down-gauging,” producing thinner yet stronger containers that use less raw material while maintaining performance.

- Consumer Perception: End-consumers increasingly view metal packaging as more premium and eco-friendly compared to Styrofoam or single-use plastic.

Buying Guide: Selecting the Right Specifications

When sourcing aluminum foil containers for commercial use, procurement managers must evaluate several technical specifications to ensure the product matches the application.

1. Gauge (Thickness)

The thickness of the aluminum is measured in microns (µm).

- Light Gauge (30–50 microns): Suitable for lightweight bakery items, tarts, and pastries.

- Medium Gauge (60–80 microns): The standard for takeout containers, takeaway trays, and lighter catering portions.

- Heavy Gauge (90+ microns): Required for large roasting pans, heavy catering steam table pans, and industrial applications where rigidity is non-negotiable.

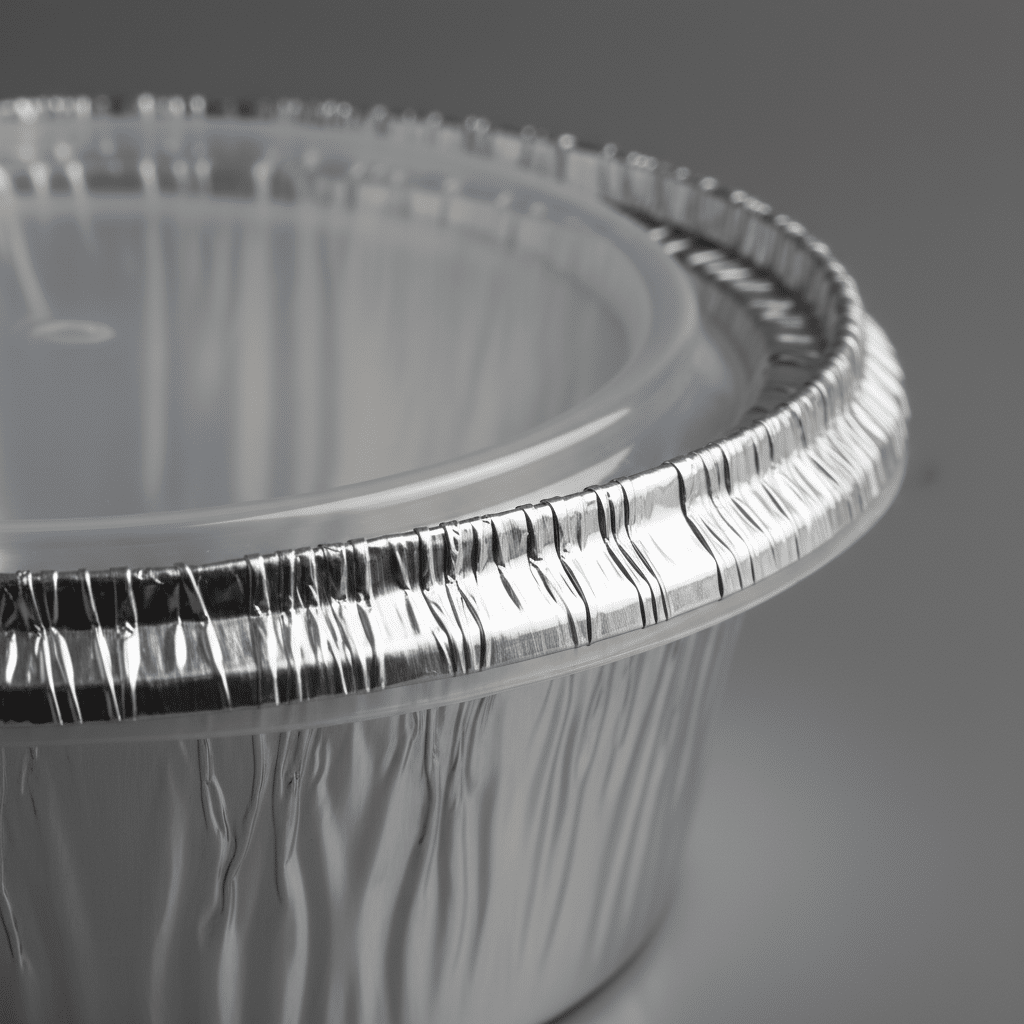

2. Rim Styles

The rim style dictates how the container can be sealed and handled.

- Full Curl (FC): A rounded rim with no sharp edges. Ideal for aluminum foil lids or snap-on plastic lids. Common in retail bakery.

- Interrupted Vertical Curl (IVC): Designed specifically for lid crimping. The vertical flange allows a flat board lid to be folded over and secured tightly, preventing leaks during transport.

- Hemmed Edge: A folded edge that provides extra rigidity and safety for handling heavy trays.

3. Alloy and Temper

Most food containers use 3000 or 8000 series aluminum alloys. The “temper” refers to the hardness. “O” temper is fully annealed (soft), making it easy to form, while “H” tempers are harder and more rigid. For heavy-duty catering pans, a harder temper is often preferred to prevent buckling.

Frequently Asked Questions (FAQ)

Can aluminum foil containers be used in the microwave?

Yes, under specific conditions. Modern shallow aluminum trays can be used in microwaves manufactured after 1980, provided the container does not touch the walls of the microwave, is not empty, and has a wide opening. However, end-users should always follow the specific instructions provided by the food manufacturer.

Are aluminum containers safe for acidic foods?

Uncoated aluminum can react with highly acidic or salty foods (like tomato sauce or sauerkraut) if stored for long periods, potentially causing pitting. For these applications, lacquered or coated aluminum containers are recommended to prevent reaction and preserve taste.

What is the typical MOQ for custom embossed containers?

Custom tooling for embossing logos or specific shapes usually requires higher Minimum Order Quantities (MOQs) compared to stock sizes. This is due to the cost of creating custom molds. It is best to consult with the manufacturer regarding specific volume thresholds for customization.

Conclusion

For the food service industry, aluminum foil containers offer a blend of versatility, performance, and sustainability that other materials struggle to match. Whether it is ensuring a pizza arrives hot and crispy or serving a banquet for hundreds, the right aluminum packaging supports operational efficiency and customer satisfaction.

Ready to optimize your food service packaging? Contact us today to discuss your specific requirements, request samples, or get a quote for bulk orders.