The Evolution of Asian Takeout Packaging

For decades, the folded paper pail has been an iconic symbol of Asian cuisine in Western markets. However, the demand for high-quality takeout packaging has evolved beyond simple aesthetics. Today, food service brands and distributors require packaging that withstands high temperatures, retains heat, and prevents leaks—all while offering sustainable disposal options.

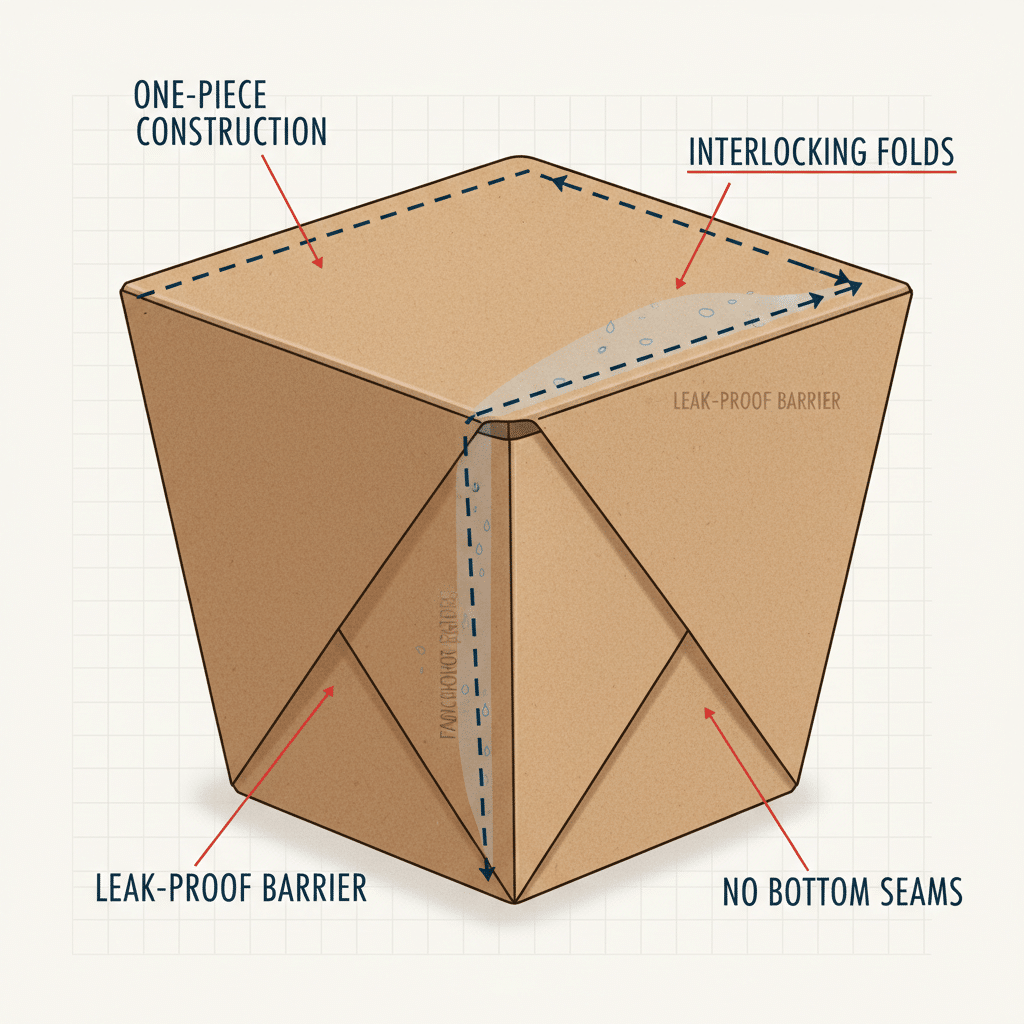

For B2B buyers and procurement managers, selecting the right container is a balance between functionality and brand presentation. One-piece foldable paper noodle boxes have emerged as a superior solution for stir-fries, rice dishes, and pasta. Unlike multi-piece containers that rely heavily on adhesives, the structural integrity of a foldable box ensures that saucy, heavy, or greasy foods remain contained from the kitchen to the customer’s table.

Structural Advantages of One-Piece Foldable Boxes

The primary advantage of the one-piece foldable design lies in its mechanical strength. By utilizing a single sheet of die-cut paperboard that is folded into shape, manufacturers eliminate bottom seams that are prone to failure.

Leak-Proof Integrity

Asian cuisine, particularly dishes like Lo Mein, Pad Thai, or curry-based rice bowls, often involves significant amounts of sauce and oil. Standard glued-bottom boxes can compromise under the weight and heat of these liquids. In contrast, a foldable noodle box typically features a continuous bottom surface with folded corners. This "cup-like" structure creates a seamless barrier against leaks, ensuring that low-viscosity sauces do not seep through the corners during transport.

Grease Resistance and Coating Options

Paperboard alone is porous and susceptible to grease absorption, which can lead to unsightly staining and structural collapse. To combat this, high-quality noodle boxes utilize barrier coatings.

- PE (Polyethylene) Lining: The most common industry standard. A thin layer of PE is applied to the interior (and sometimes exterior) of the Kraft or white paperboard. It provides excellent resistance to oil and moisture.

- Aqueous Coatings: Water-based coatings that offer grease resistance while often being easier to recycle in standard paper streams.

- PLA (Polylactic Acid): A bioplastic alternative derived from renewable resources like corn starch, suitable for brands focusing on compostability.

Suitability for Heavy and Saucy Dishes

The versatility of the foldable noodle box extends beyond traditional Asian noodles. Its robust construction makes it ideal for a variety of heavy and hot menu items.

Heat Retention and Venting

The folding top closure system serves a dual purpose. First, it securely locks the package without the need for separate plastic lids, reducing inventory complexity. Second, the design can be adjusted to allow steam to escape. Proper venting is critical for fried items like Tempura or General Tso’s Chicken to prevent them from becoming soggy, while still retaining enough heat to keep the meal warm.

Stackability for Logistics

From an operations perspective, these boxes are designed to nest efficiently when empty and stack securely when full. The flat top created by the folded flaps allows for stable vertical stacking in delivery bags, maximizing volume per trip and protecting the food inside from crushing.

Technical Specifications for Procurement

When sourcing paper noodle boxes, buyers must define specific technical parameters to ensure the product meets their operational needs. Below are typical specifications to consider.

| Feature | Typical Specification Range | Notes |

|---|---|---|

| Material | Food Grade Kraft or White Bleached Board | Kraft offers a natural look; White offers better print vibrancy. |

| Paper Weight (GSM) | 280gsm – 350gsm | Higher GSM required for larger volumes (e.g., 32oz) to prevent bowing. |

| Coating | Single PE (Interior) or Double PE | Double PE recommended if boxes are stored in freezers or refrigerators to prevent condensation damage. |

| Capacity | 16oz, 26oz, 32oz | Standard industry sizes facilitate portion control. |

| Printing | Flexographic or Offset | Offset allows for photo-quality branding; Flexo is cost-effective for simple logos. |

Manufacturing and Quality Assurance

Reliable manufacturing involves precise die-cutting and forming processes. In a B2B context, consistency is key. Buyers should inquire about the manufacturer’s quality control steps regarding:

- Adhesion Testing: Even in foldable designs, side seams are often glued. These bonds must be tested for heat resistance to ensure they do not pop open under the steam of hot food.

- Leak Testing: Random sampling should be performed using dyed water or oil solutions to verify the integrity of the folded corners and coating coverage.

- Dimensional Accuracy: Ensuring the locking flaps fit securely every time is vital for high-speed kitchen environments.

Buying Guide: Customization and Ordering

Ordering custom noodle boxes requires planning around lead times and minimum order quantities (MOQs).

Custom Branding

The broad, flat surfaces of a noodle box offer excellent real estate for branding. Utilizing CMYK printing allows for vibrant designs that stand out on delivery apps and social media. When submitting artwork, ensure vector files (AI or PDF) are provided to the manufacturer to ensure sharp print lines.

MOQ and Lead Times

Custom printing typically incurs higher MOQs compared to plain stock. While plain boxes might be available for immediate shipment in smaller pallets, custom runs often require 10,000 to 30,000 units minimum, with lead times ranging from 4 to 8 weeks depending on production schedules and shipping logistics.

FAQ: Sourcing Noodle Boxes

Are these boxes microwave safe?

generally, yes. Paper noodle boxes without metal handles are microwave safe. However, the type of coating (PE vs. PLA) can affect heat tolerance. Always confirm the temperature rating with the manufacturer.

Can I use these for soups?

While leak-resistant, standard noodle boxes are not designed for pure liquids like broth-heavy soups. They are best suited for viscous sauces and solid foods. For soups, a dedicated heavy-duty soup container with a tight-sealing lid is recommended.

What is the difference between single and double PE coating?

Single PE coating is applied only to the inside to prevent grease absorption. Double PE coating is applied to both the inside and outside. Double PE is ideal if the boxes will be refrigerated, as it protects the paper from external condensation.

Do you offer eco-friendly alternatives to PE lining?

Yes, options such as PLA linings or water-based barrier coatings are increasingly available for markets with strict plastic reduction regulations.

Request a Quote

Ready to upgrade your food packaging with high-quality, grease-resistant noodle boxes? Contact us today to discuss your specifications, request samples, or get a competitive quote for your bulk order.